- Author Jason Gerald gerald@how-what-advice.com.

- Public 2023-12-16 10:50.

- Last modified 2025-06-01 06:05.

Corrosion is a process by which iron is degraded by the presence of various oxidizing agents in the environment. Corrosion takes many forms and can have many causes. One common example is the rusting process, where iron oxidizes in the presence of moisture. Corrosion is a serious problem for manufacturers of buildings, boats, planes, cars, and other metal products. For example, when iron is used as part of a bridge, the structural integrity of the iron, which can be damaged by corrosion, is critical to the safety of the people using the bridge. See Step 1 below to start learning how to protect iron from the threat of corrosion and how to slow down the rate of corrosion.

Step

Method 1 of 3: Understanding Common Types of Iron Corrosion

Because so many different types of iron are used today, builders and manufacturers need to protect against many types of corrosion. Each iron has unique electrochemical properties that determine what type of corrosion (if any) it is susceptible to. The table below describes some common irons and the types of corrosion they can undergo.

| Iron | Iron Corrosion Vulnerability | General Prevention Techniques | Galvanic Activity* |

|---|---|---|---|

| Stainless Steel (Passive) | Uniform attack, galvanic, perforated, cracked (all mainly in seawater) | Cleaning, protective coating or seal | Low (initial forms of corrosion form a protective oxidation layer) |

| Iron | Uniform attack, galvanic, crack | Cleaning, protective coating or seal, galvanization, anti-rust | Tall |

| Brass | Uniform attack, dezincification, stress | Cleaning, protective coating or seal (usually oil or varnish), adding lead, aluminum, or arsenic to alloys | Currently |

| Aluminum | Galvanic, holes, cracks | Cleaning, protective coating or seal, anode, galvanization, cathodic protection, electrical insulation | High (initial corrosion forms a resisting oxidation layer) |

| Copper | Galvanic, hole, aesthetic stain | Cleaning, protective coating or sealing, adding nickel to metal alloys (especially for brine) | Low (initial corrosion forms a retaining patina) |

*Please be aware that the column “Galvanic Activity” refers to the related chemical activity of iron as described by the galvanic table of the reference source. For the purposes of this table, “the higher the galvanic activity of iron, the faster it will undergo galvanic corrosion when combined with less active iron.”

Step 1. Prevent uniform attack corrosion by protecting the iron surface

Uniform attack corrosion (sometimes shortened to “uniform” corrosion) is a type of corrosion that occurs, accordingly, in a uniform manner over exposed metal surfaces. In this type of corrosion, the entire surface of the iron is attacked by corrosion and, thus, corrosion proceeds at a uniform rate. For example, if an unprotected metal roof is regularly exposed to rain, the entire roof surface will be in contact with the same amount of water and will thus corrode at a uniform rate. The easiest way to protect against uniform attack is usually to place a protective barrier between the berry and the corrosive agent. This could be a number of things - paint, oil seals, “or” an electrochemical solution such as a galvanizing zinc coating.

In underground or immersion situations, a cathodic shield is also a good option

Step 2. Prevent galvanic corrosion by cutting off the flow of ions from one iron to another

One important form of corrosion that can occur regardless of the physical strength of the iron involved is galvanic corrosion. Galvanic corrosion occurs when two irons with different electrode potentials come into contact with the presence of an electrolyte (such as salt water) which creates an electrical conduction path between them. When this happens, iron ions flow from the more active iron to the less active iron, causing the more active iron to corrode more quickly and the less active iron to corrode more slowly. In practical terms, this means that corrosion will develop on the more active iron at the point of contact between the two irons.

- Any method of protection that prevents the flow of ions between the irons can stop galvanic corrosion. Giving the iron a protective layer can help prevent electrolytes from the environment creating an electrical conduction path between the two irons, which electrochemical shielding processes such as galvanization and anode also work well. You can also prevent galvanic corrosion of electrically insulating areas of iron in contact.

- In addition, the use of cathodic or anode protection can protect the important iron from galvanic corrosion. See below for more information.

Step 3. Prevent pitting corrosion by protecting the iron surface, avoiding chloride sources in the environment, and avoiding nicks and scratches

Pitting is a form of corrosion that takes place on a microscopic scale but can have major consequences. Holes are a major concern for iron that derives its corrosion resistance from a thin layer of passive compound on its surface, as this form of corrosion can lead to structural failure in situations where a protective coating would normally prevent it. Holes occur where a small piece of iron loses its passive protective layer. When this occurs, galvanic corrosion occurs on a microscopic scale, leading to the formation of tiny holes in the iron. In this hole, the environment becomes high in acid, which speeds up the process. Holes are usually prevented by applying a protective layer to the metal surface and/or using cathodic protection.

Exposure to a high chloride environment (such as, for example, salt water) can speed up the perforation process

Step 4. Prevent corrosion cracking by minimizing tight spaces in the object design

Crack corrosion occurs in metal object spaces where access to the surrounding fluid (air or liquid) is poor - for example, under bolts, under washers, under barnacles, or between hinge joints. Crack corrosion occurs where the gap between the metal surfaces is wide enough to allow liquid to enter but narrow enough so that the liquid is difficult to escape and becomes stagnant. The environment in this small space becomes corrosive and the iron begins to corrode in a process similar to crack corrosion. Preventing corrosion cracking is generally a design problem. By minimizing the presence of narrow gaps in the construction of metal objects through covering these gaps or providing circulation, it is possible to minimize crack corrosion.

Crack corrosion is a particular concern when handling iron such as aluminum which has a passive outer protective layer, as crack corrosion mechanisms can contribute to the breakdown of this coating

Step 5. Prevent stress crack corrosion by using only secure loads and/or annealing

Stress corrosion cracking (SCC) is a form of corrosion-related structural failure that is a concern for engineers designing building structures that support critical loads. With the occurrence of SCC, the iron supporting the load forms cracks and fractures below its load limit - in severe cases, to a lesser extent. In the presence of corrosive ions, microscopic tiny cracks in the iron caused by the tensile stress of the heavy charges spread as the corrosive ions reach the tip of the crack. This causes the crack to slowly enlarge and can lead to structural failure. SCC is particularly dangerous because it can occur even in the presence of materials that are generally less corrosive to iron. This means that this harmful corrosion occurs while the rest of the iron surface appears unaffected.

- Preventing SCC is partly a design problem. For example, selecting materials that are SCC resistant in the environment in which the iron will operate and ensuring that the ferrous material is properly stress tested can help prevent SCC. In addition, the process of strengthening the iron can remove residual stress from the design.

- SCC has been known to be exacerbated by high temperatures and the presence of dissolved chloride-containing fluids.

Method 2 of 3: Preventing Corrosion with Home Solutions

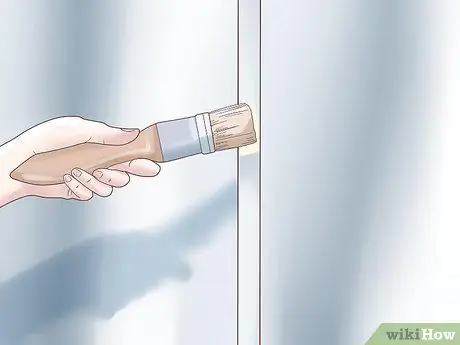

Step 1. Paint the iron surface

Possibly the most common and inexpensive method of protecting iron from corrosion is to simply cover it with a coat of paint. The corrosion process involves moisture and oxidizing agents interacting with the iron surface. That way, if the iron is coated with a protective paint barrier, neither moisture nor oxidizing agents can come into contact with the iron itself and corrosion does not occur.

- However, the paint itself is prone to degradation. Repaint whenever something is chipped, worn or damaged. If the paint degrades so that the iron is exposed, be sure to inspect for corrosion or damage to the exposed iron.

-

There are many methods for painting metal surfaces. Metalworkers often use several of these methods to ensure all metal objects get a thorough coating. Below are some sample methods with comments on their use:

- Brush - used for hard to reach spaces.

- Roller - used to cover large spaces. Cheap and easy.

- Air spray - used to cover large spaces. Faster but not as easy as a roller (wasteful of paint).

- Airless spray/Electrostatic airless spray - used to cover large spaces. Fast and allows varying degrees of thick/thin consistency. Not as wasteful as regular spray water. Equipment is quite expensive.

Step 2. Use marine paint for water exposed iron

Metal objects that are regularly (or constantly) in contact with water, such as boats, require special paint to protect against the high probability of corrosion. In this situation, “normal” corrosion in the form of rusting is not the only concern (although it is quite large), as marine life (barnacles, etc.) can grow on unprotected iron which can be a source of wear and tear and additional corrosion. To protect metal objects such as boats and others, be sure to use a high-quality epoxy marine paint. This type of paint not only protects the iron from moisture, but also prevents the growth of marine life on its surface.

Step 3. Apply protective lubrication to moving metal parts

For flat and static metal surfaces, paint does an excellent job of keeping moisture away and preventing corrosion without affecting the usability of the iron. However, paint is usually not suitable for moving metal parts. For example, if you paint on a door hinge, when the paint dries, it will hold the hinge, blocking its movement. If you force the door open, the paint will crack, leaving room for moisture to reach the iron. A better choice for ferrous parts such as hinges, joints, shafts, and so on is a suitable water-insoluble lubrication. This thorough coat of lubricant will repel moisture while ensuring smooth and easy movement of your metal parts.

Because lubricants don't dry in place like paint, they can degrade over time and require regular reuse. Periodically re-apply lubrication to metal parts to ensure they remain effective as a protective seal

Step 4. Clean the metal surface thoroughly before painting or lubricating

Whether you use regular paint, marine paint, or protective lubrication/sealing, you should make sure your iron is clean and dry before starting the application process. Make sure the iron is free of any existing dirt, grease, weld residue, or corrosion, as this could waste your effort by contributing to corrosion in the future.

- Soil, oil, and other debris can interfere with paint and lubrication by preventing the paint or lubricant from adhering directly to the metal surface. For example, if you paint on a sheet of steel with a scrap of iron on top, the paint will dry on top of the grind, leaving empty space in the iron underneath. If and when the sharpener falls. The exposed part will be susceptible to corrosion.

- If painting or lubricating metal surfaces with pre-existing corrosion, your goal should be to make the surface as smooth and normal as possible to ensure the best possible seal adhesion to the iron. Use a wire brush, sand paper, and/or chemical rust remover to remove as much corrosion as possible.

Step 5. Keep unprotected iron products away from moisture

As noted above, most forms of corrosion are exacerbated by moisture. If you are unable to apply a protective coat of paint or seal to your iron, you should be careful to make sure it is not exposed to moisture. Making an effort to keep unprotected iron tools dry can increase their usefulness and extend their effective life. If your iron is exposed to water or moisture, be sure to clean and dry it immediately after use to prevent corrosion from starting.

In addition to monitoring exposure to moisture while using, be sure to store metal objects indoors, in a clean and dry place. For large items that don't fit in a cupboard or cabinet, cover the item with a cloth. This helps to repel moisture from the air and prevents dust from accumulating on the surface

Step 6. Make sure the metal surface is as clean as possible

After each use of a metal object, regardless of whether the metal is painted or not, be sure to clean its functional surface, removing any dirt, grease, or dust. The accumulation of dirt on the metal surface can contribute to the wear and tear of the iron and/or its protective coating, leading to corrosion over time.

Method 3 of 3: Preventing Corrosion with Advanced Electrochemical Solutions

Step 1. Use the galvanization process

Galvanized iron is iron that has been coated with a thin layer of zinc to protect it from corrosion. Zinc is more chemically active than the underlying iron, so it oxidizes when exposed to air. Once the zinc layer is oxidized, it forms a protective layer, preventing further corrosion of the underlying iron. The most common type of galvanization today is a process called hot dip galvanization in which a piece of iron (usually steel) is immersed in hot molten zinc to obtain a uniform coating.

-

This process involves handling industrial chemicals, some of which are hazardous at room temperature, at very high temperatures and should not be attempted by anyone other than a trained professional. Below are the basic steps of the hot dip galvanizing process for steel:

- The steel is cleaned with a hot solution to remove dirt, oil, paint, etc., then rinsed thoroughly.

- Steel is immersed in acid to remove mill scale, then rinsed.

- A material called “flux” is applied to the steel and allowed to dry. This helps the final zinc layer adhere to the steel.

- The steel is immersed in hot zinc and allowed to reach the zinc temperature.

- The steel is cooled in a “cooling tank” filled with water.

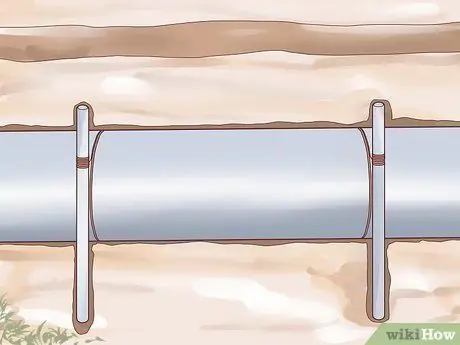

Step 2. Use the sacrificial anode

One way to protect a metal object from corrosion is to electrically attach a small, reactive metal called a "sacrifice anode" to it. Because of the electrochemical relationship between the larger iron body and the small reactive body (which is briefly described below), only the small and reactive iron will undergo corrosion, leaving the large and important iron intact. When the sacrificial anode corrodes completely, it must be replaced or the larger iron will corrode. This method of corrosion protection is typically used for buried structures such as underground storage tanks, or objects that are in constant contact with water, such as boats.

- The sacrificial anode is made of several different types of reactive iron. Zinc, aluminum, and magnesium are the three most common irons used for this purpose. Because of the chemical properties of these materials, zinc and aluminum are commonly used for ferrous materials in salt water, whereas magnesium is more suitable for freshwater purposes.

- Sacrificial anodes can be used because of the chemical process of corrosion itself. When an iron object corrodes, areas that are chemically similar to the anode and cathode in an electrochemical cell are naturally formed. Electrons flow from the anode at the iron surface to the surrounding electrolyte. Because the sacrificial anode is very reactive compared to the iron being protected, the object itself becomes highly cathodic by comparison and, thus, electrons flow out of the sacrificial anode, causing it to corrode but not the rest of the iron.

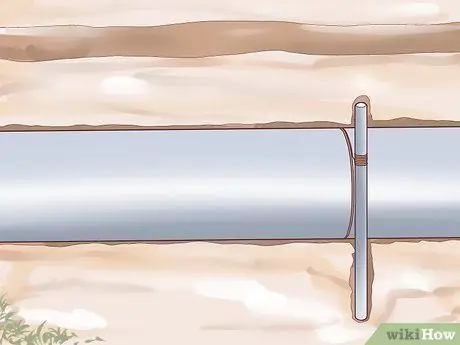

Step 3. Use “impressed current”

Since the electrochemical process behind the corrosion of iron involves the flow of electricity in the form of electrons flowing out of the iron, it is possible to use an external electric current source to control the corrosive flow and prevent corrosion. This process (called “impressed current”) is a continuous negative iron charge on the iron being protected. This charge dominates the flow causing electrons to flow out of the iron, preventing corrosion. This type of protection is typically used for buried iron structures such as storage tanks and pipes.

- Be aware that the type of electric current used for impressed current protection systems is usually direct current (DC).

- Typically, an impressed current that prevents corrosion is generated by burying two iron anodes in the ground near a protected metal object. Electric current is sent through the insulating wire at the anode, which then flows through the ground and into the metal object. Electricity flows through iron objects and then returns to the source of electricity (generators, rectifiers, etc.) through insulating wires.

Step 4. Use anodizing

Anodizing is a special surface protective layer used to protect iron from corrosion. If you've ever seen a light-colored iron carabiner, you've seen a colored anodized iron surface. Instead of involving the physical application of a protective coating, such as paint, anodizing uses an electric current to give the iron a protective layer that prevents almost all forms of corrosion.

- The chemical process behind anodization involves the fact that many irons, such as aluminum, naturally form chemical products called oxides when in contact with oxygen in the air. This results in the iron normally having a thin outer oxide layer that protects (to varying degrees, depending on the iron) against further corrosion. The electric current used in the anodizing process usually creates a thicker build of this oxide on the surface of the iron than usual, providing great protection from corrosion.

-

There are several different ways to donate iron. Below are the basic steps of one of the anodizing processes. See How to Anodize Aluminum for more information.

- Aluminum is cleaned and de-oiled.

- Impurities on the aluminum surface are removed with a de-smut solution.

- Aluminum is placed in an acid bath at constant current and temperature (for example, 12amps/sq ft and 70-72 degrees F (21-22 degrees C).

- Aluminum is removed and rinsed.

- The aluminum is optionally introduced into the dye at 100-140 degrees F (38-60 degrees C).

- Aluminum is sealed by placing it in boiling water for 20-30 minutes.

Step 5. Use passive iron

As noted above, some iron naturally forms a protective oxide layer when exposed to air. Some iron forms this oxide layer so effectively that it becomes chemically inactive. We say that iron is “passive” in reference to a “passive” process in which it becomes less reactive. Depending on their use, passive iron objects may not “need” additional protection to make them corrosion resistant.

-

One well-known example of passive iron is stainless steel. Stainless steel is a common alloy of steel and chromium that resists corrosion under most conditions without requiring protection. For most everyday uses, corrosion is usually not a concern with stainless steel.

However, it must be said that under certain conditions, stainless steel is not 100% corrosion resistant - for example, in salt water. Similarly, many passive irons become non-passive under extreme weather conditions and are thus not suitable for all applications

Tips

- Be aware of inter-granular corrosion. This affects the iron's ability to be molded or manipulated, and reduces the iron's overall strength.

- The American Boat and Yacht Council generally recommend tying the boat. However, aluminum and steel boats should not be strapped to prevent the iron from corroding.

Warning

- Never leave severely corroded metal parts in vehicles or boats. The degree of corrosion varies, but any corrosion can indicate serious structural damage. For safety, replace or remove all signs of iron corrosion.

- When using a sacrificial anode, do not paint it. That would make it impossible for electrons to pass into the surroundings, taking away its corrosion-preventing power.