- Author Jason Gerald gerald@how-what-advice.com.

- Public 2023-12-16 10:50.

- Last modified 2025-01-23 12:04.

If you've ever worked in a woodworking or metal shop, chances are you've seen the Dremel. The Dremel is a drill-like tool whose eyes can be attached to various heads and accessories. You can use Dremel on wood, metal, electronics, plastic, and a variety of other materials. Dremel is also very useful for making arts and crafts, as well as small home improvement projects. This tool is also useful for working on small, hard-to-reach parts. After learning the basics of usage and testing it on several projects, you'll realize the versatility of this tool.

Step

Part 1 of 3: Learning the Basics

Step 1. Choose Dremel

Dremel was one of the first companies to manufacture rotary tools, and his name has stuck with these tools to this day. Dremel also makes a variety of other tools, including electric screwdrivers and scroll saws. Try searching the tools they currently sell to find one that fits your needs. The prices of these tools vary so you should make sure you are getting the right one. Dremel tool options include:

- Wired or wireless models

- Light and portable, or strong and sturdy

- Longer battery life

- Fixed speed (usually easier and easier to use) or variable speed (better for complex and more expensive sanding projects).

Step 2. Read the user manual

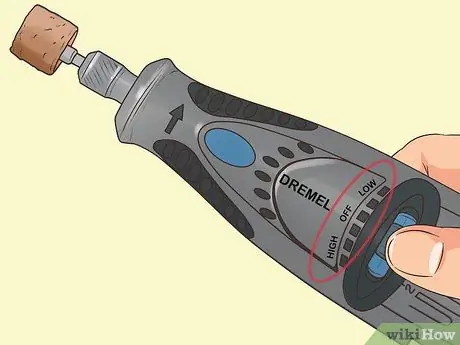

When you purchase this kit, you will receive a Dremel tool, a wide variety of drill bits and attachments, and a user manual. You should read the user manual before using Dremel for the first time). This will help you familiarize yourself with the device controls. Locate the speed setting, on/off button, and the button to change the drill bit.

Since your device model may differ from the previous model year, we recommend that you read the user manual carefully

Step 3. Wear appropriate safety equipment

You should always wear work or rubber gloves when using the Dremel. Gloves will protect your hands from splinters and sharp edges. It's also a good idea to wear safety glasses, especially when cutting, polishing, or sanding with a Dremel.

Try to keep your workspace clean. Also make sure your workspace is not accessible to children and other people while using the tool

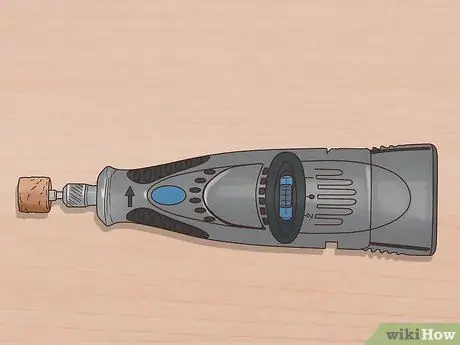

Step 4. Practice inserting and tightening the drill bit

The drill bit is attached by inserting the drill bit into the hole at the end of the Dremel and pushing it back slightly. Tighten the collet nut so that the drill bit is tight and does not wobble. To release the drill bit, press the rod lock button while turning the collet. Your drill bit will loosen a bit so it can be replaced.

- Try to practice inserting and replacing drill bits when the Dremel is off and not plugged into a power socket.

- Some models are equipped with a collet designed for easy connection and removal.

- You can also find collets in various sizes to work with accessory shanks of various sizes.

- In some cases, you may need to use a mandrel, which is a type of shank with a threaded head. This is a permanent shank type used with drill bits for polishing, cutting, or sanding.

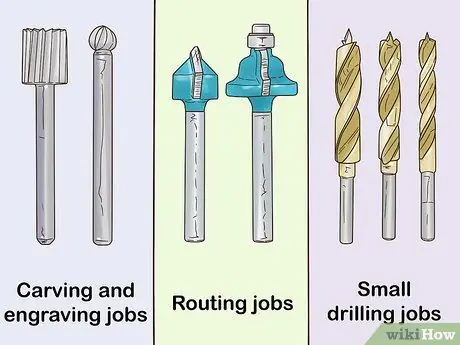

Step 5. Use the appropriate drill bit for your job

You must choose the drill bit according to the material being worked on. Dremel manufactures many drill bits in a wide variety of materials for use in almost any material. For example, for:

- Engraving and chiseling: use high speed cutter blades, engraving cutter blades, structured tooth carbide cutter blades, tungsten carbide cutter blades, and diamond wheel tips.

- Routing: use a router drill bit (straight, keyhole, angle, or grooved). When using a router, try to only use a router drill bit.

- Minor drilling: use a drill bit (sold individually or as a set).

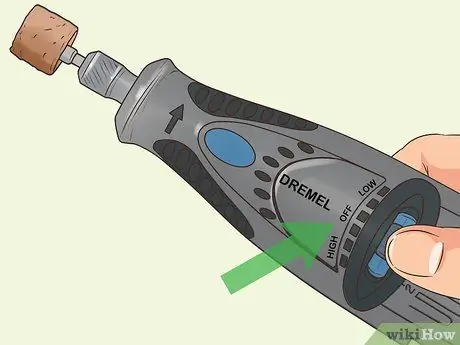

Step 6. Make sure your Dremel is turned off before plugging it into a power socket

Once plugged in, turn the Dremel to its lowest setting and practice changing settings to different speeds.

- To get used to the Dremel, try holding the device with a variety of grips. For complex work, it's best to hold it like holding a pencil. For large jobs, hold the tool firmly so that your fingers grip the handle tightly.

- Use tongs or vise so that the material you are working with does not move.

- Check the user manual to determine the appropriate speed for the job to be performed.

Step 7. Clean the Dremel after use

Remove the drill bit and put it back in the box. Take time to wipe the drill with a cloth after each use. Dremel will last a long time if you keep it clean. Read the user manual before disassembling the Dremel for a thorough cleaning.

You will need to use compressed air frequently to clean the Dremel airways. This will prevent damage to the device's power grid

Part 2 of 3: Cutting with Dremel

Step 1. Use Dremel to make small cuts and details

The Dremel is light in weight and easy to move, making it perfect for making small details and cuts. You may find it difficult to make long, smooth curves because most of the work is done manually. However, you can make several straight cuts to get the edges you want and smooth them out with an emery drill bit.

Don't use the Dremel to make long, large cuts that are better suited to a saw

Step 2. Try not to move the object being worked on

Depending on the object or material being cut, secure it with tongs or a vise. Do not hold the cut object by hand.

Step 3. Cut the object at a speed suitable for the material

If the speed is too fast or too slow it will damage the motor, drill bit, or the material you are working with. If in doubt, check the user manual for the manufacturer's recommended speeds for Dremel and specific materials.

- If you are cutting thick or strong material, slice several times to cut the material. If the material being worked on is too thick or strong to cut easily, you may want to use an oscillating saw.

- If you see smoke and discoloration, the Dremel's speed is too high. If you hear the motor slow down, you may be pressing the Dremel too hard. Take the pressure off and reset your Dremel speed.

Step 4. Try cutting the plastic

Attach the saw blade to the Dremel. You should wear eye and ear protection before cutting plastic. Set the Dremel speed to a number between 4 and 8 so that it has enough power, but don't force the motor to overheat. Sand all the rough edges on the cut.

- Don't press too hard while cutting so as not to damage your Dremel and drill bit.

- Depending on the project you're working on, you may be able to outline the cutout on the plastic. Thus, cuts can be made more easily and accurately.

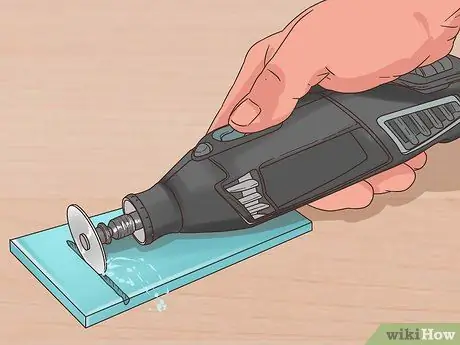

Step 5. Practice cutting metal

Install metal cutting wheels on your Dremel. Wear eye and ear protection before starting to cut. Turn on the Dremel and set the strength between 8 and 10. Make sure the metal is firmly held so that it doesn't move when cut. Gently touch the Dremel to the metal for a few seconds until the metal appears to be cut. You will also see sparks flying.

Fiber-reinforced discs are more durable than ceramic discs, which can break when cutting metal

Part 3 of 3: Sharpening, Sanding and Polishing with Dremel

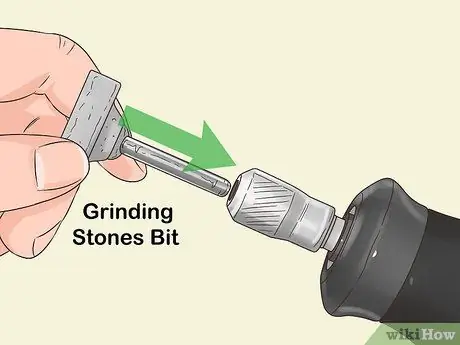

Step 1. Sharpen using Dremel

Attach the whetstone to the Dremel mandrel/rod. Slide the whetstone into the front of the Dremel until it is fully seated. Turn on the Dremel and grind on a low setting so that the object being sharpened doesn't get too hot. Continue to gently grind the ingredients until they are worn.

- You can use a whetstone, grinding wheel, chainsaw sharpening stone, abrasive wheel, and abrasive tip to sharpen materials. Carbide drill bits are usually most effective for sharpening metal, porcelain, or ceramic.

- Use a cylindrical or conical tip to sharpen round objects. If you're sharpening notches or corners on the inside of something, use a flat disc. Use a cylindrical or conical tip to sharpen round objects.

Step 2. Start sharpening or sanding with your Dremel

Select an emery drill bit and attach it securely to your Dremel. Sanding drill bits are available in a variety of grits (roughness grades) and are compatible with the same mandrel. Tighten the screw at the end of the sanding drill bit. Turn on the Dremel and set it to a number between 2 and 10. Choose a low setting if you are sharpening or polishing plastic or wood. Choose a higher setting if you are sanding metal. While holding the material still, touch the drill bit against the material to sharpen or sand it.

- Make sure the sanding drill bit is in good condition so that it doesn't scratch and leave marks on the material being worked on. The drill bit must be firmly attached and must not be worn out. It's a good idea to prepare a few spare drill bits so they can be replaced immediately when needed.

- To sand, you can use a sanding tape, sanding disc, flap wheel, and shaping wheel, as well as a detail abrasive brush.

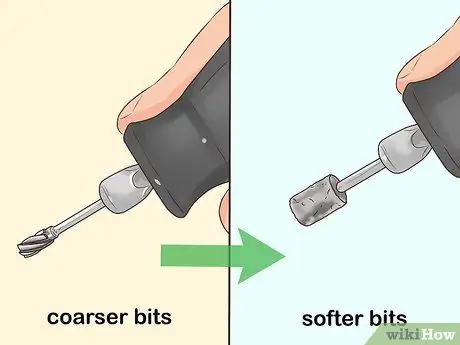

Step 3. Switch from a coarse drill bit to a fine drill bit

If you are doing a big job, start with a coarse drill bit before moving on to a finer drill bit. This will allow you to quickly sand away large scratches so the work can be controlled more easily. If you skip using a coarse drill bit and go straight to a fine drill bit, your job will take longer and the drill bit will wear out quickly.

Check your drill bit every minute or two for wear or damage. Don't forget to turn off and unplug the Dremel power cord before doing so

Step 4. Polish the metal or plastic

The Dremel is a great tool for polishing detailed carvings or in tight locations. Rub the polishing compound over the surface of the workpiece and secure the tip or wheel of the polishing cloth to the Dremel. Turn on the Dremel on low speed (2) and touch it to the polishing compound. Polish your material in circular motions until complete. Do not use high speed for polishing (maximum speed 4).

- You can polish the material without compound products, but the results will be more shiny when used.

- For cleaning and polishing materials, use a polishing rubber tip, polishing cloth wheel, and polishing brush. Make sure you use a polishing brush with a roughness appropriate for your job. These drill bits are great for peeling paint off old furniture metal or cleaning utensils and grills.

Tips

- Remember not to press too hard when cutting or sanding the material. Let your Dremel blade and whetstone do the work.

- Make sure the material you're working with is firmly held so that it doesn't move. If you can still move, hold it with tongs or vise.

- Turn on the Dremel so it spins at high speed before you touch the material.

- The Dremel has a brush in the device that lasts as much as 50-60 hours. If the Dremel doesn't seem to be working well, it's best to take it to a service center.

Warning

- Make sure your workplace is clean. It's best to work outdoors or in a well-ventilated area as drilling, sanding, grinding, and cutting will leave debris on your body and floors, as well as in the air in the workplace.

- ALWAYS wear safety glasses when using the Dremel.