- Author Jason Gerald gerald@how-what-advice.com.

- Public 2024-01-19 22:11.

- Last modified 2025-06-01 06:05.

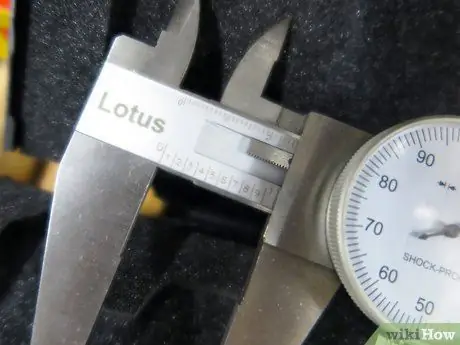

Caliper is a measuring tool used to measure the width of a gap or object accurately, more accurately than using a tape measure or ruler. In addition to digital models that adopt an electronic display, a caliper can show measurements on a pair of scales (vernier caliper) or with a scale and a dial (dial caliper).

Step

Step 1. Identify your calipers

Use the instructions for use of the vernier caliper if your tool has two calipers. If your instrument has a scale and a dial, then see the instructions for using the dial caliper.

If you use digital calipers, the measurements will be shown on the electronic display, especially with the option to change between mm (millimeters) and inches (in). Before measuring, close the jaw of the larger compass and press the Zero, Tare or ABS button to set the closed position to zero

Method 1 of 2: Reading the Vernier Caliper

Step 1. Check for zero errors

Loosen the screw to put the sliding scale in place. Slide the scale until the jaws that are larger than the caliper press against each other. Compare the 0 position on the sliding scale with the fixed scale written on the caliper body. If the two 0's intersect accurately, then skip the step of taking a measurement. If not, then proceed to the next step to fix the error.

Fixed Zero Error

Step 1. Use the adjustment wheel if available

Although this part is not commonly found, some vernier calipers have an adjustment wheel on the sliding scale that can be pressed to adjust the sliding scale without changing the caliper jaws. If your caliper model has these wheels, then press until the zeros on the fixed scale and sliding scales intersect, then skip on the sizing reading. If not, then proceed to the next step.

Look at both jaws carefully to make sure that you don't press the fine adjustment screw which can open and close the jaw by a small amount

Step 2. Calculate the positive zero error

If the 0 on the sliding scale is in the right from 0 on the fixed scale, read the size on the fixed scale that intersects with 0 on the sliding scale. This is a positive zero error, so write it with a + sign.

For example, if the 0 on the sliding scale is tangent to 0.9mm on the fixed scale, write "zero error: +0.9 mm."

Step 3. Calculate the negative zero error

If the 0 on the sliding scale is in the left from 0 on a fixed scale, do the steps below:

- Locate the line on the sliding scale that intersects exactly on the line of the fixed scale when the jaw is closed.

- Move the sliding scale so that its line is tangent to the largest value. Repeat until the 0 on the sliding scale is to the right of the 0 on the fixed scale. Record the amount of distance moved.

- Read the size on a fixed scale that is tangent to the number 0 on the sliding scale.

- Subtract the amount of distance moved by the value you just read. Write zero errors including the minus sign.

- For example, 7 on the sliding scale is tangent to 5mm on the fixed scale. Move the sliding scale further than the fixed scale, then line the 7 with the next fixed scale size: 7mm. Notice that you move the distance by 7 - 5 = 2mm. The 0 on the sliding scale is now 0.7mm in size. The zero error is equal to 0.7mm - 2mm = -1.3mm.

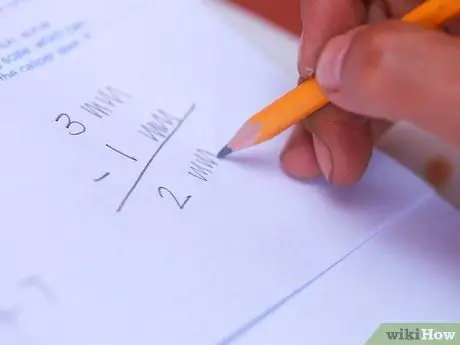

Step 4. Subtract all measurements to zero error

Each time you take a measurement, Subtract the result by zero error to get the actual size of the object. Do not forget to write a zero error sign (+ or -) in the measurement result.

- For example, if the zero error is +0.9mm, and you measure with a value of 5.52mm, then the actual size is 5.52 - 0.9 = 4.62mm.

- For example, if the zero error is -1, 3mm, and you measure with a value of 3.20mm, then the actual size is 3.20 - (-1, 3) = 3, 20 + 1, 3 = 4.50mm.

Doing Size Reading

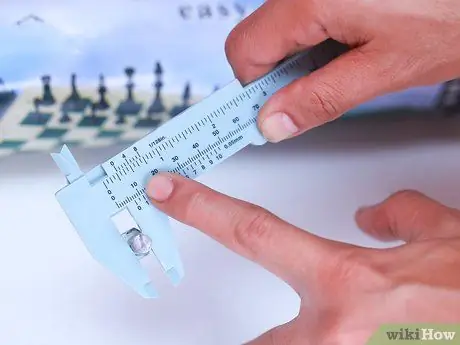

Step 1. Adjust the jaw to take the measurement

Pinch the object with wide, flat jaws to measure the outer dimensions. Insert the small, sharp jaws into the object and then slide them outwards to measure the inner dimensions. Lock the locking screw so that the scale does not change.

Slide the scale to open or close the jaws. If your caliper has a fine adjustment screw, you can use this part to make more precise adjustments

Step 2. Read the size on a fixed scale

After the caliper jaw is in the right position, pay attention to the fixed scale written on the caliper body part. There are usually fixed imperial and metric scales; one can work. Perform the following steps to find the first pair of digits in your measurement:

- Find the value of 0 on the smaller sliding scale, next to the fixed scale you are using.

- Find the closest value to the left of the 0 value or directly above the line on a fixed scale.

- Read the measurement values as you would a ruler - but remember that the imperial side of the caliper divides each inch into 10 parts, not into 16 parts like most rulers do.

Step 3. Check the sliding scale for additional digits

Check the sliding scale carefully, starting at 0 and then moving to the right. Stop when you find the line directly above each number on a fixed scale. Read this value on a sliding scale as you would a regular ruler using the units written on the sliding scale.

The values on the fixed scale have no effect. You just need to read the size on the sliding scale

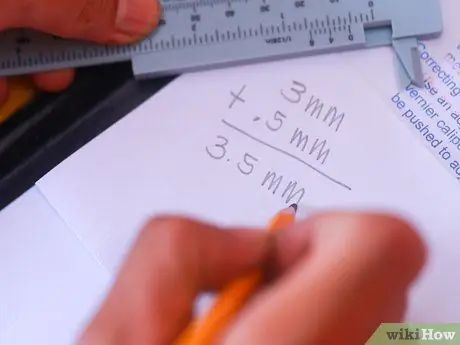

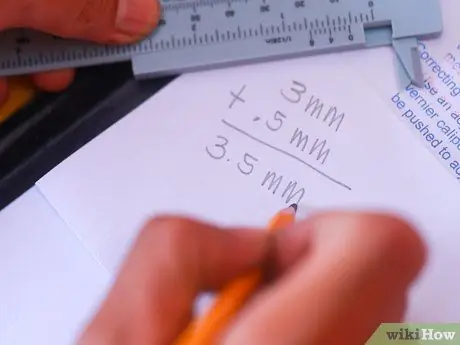

Step 4. Add both values to get the final result

Write down the size on the fixed scale and then write the digits on the sliding scale. Check the units written on each scale to be sure.

- For example, a value on a fixed scale is 1, 3 and is marked with a measure of "inches." Your sliding scale measures 4.3 and is marked with a size of "0.01 inches," which means it measures 0.043 inches. So the final measurement is 1.3 inches + 0.043 inches - 1.343 inches.

- If you encounter zero errors before, then don't forget to subtract them from your measurements.

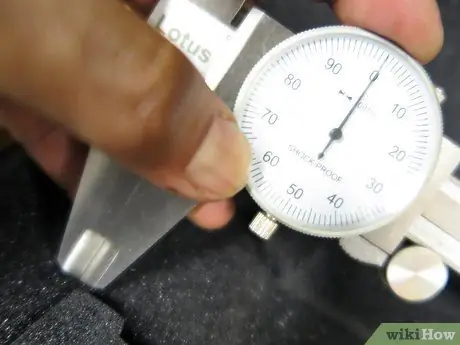

Method 2 of 2: Reading the Dial Caliper

Step 1. Check for zero errors

Close the jaw perfectly. If the hand on the dial does not show zero, rotate the dial with your finger until the zero is on the hand. You may need to loosen the screws on the top or bottom of the dial before doing so. If so, then remember to lock the screws again after making adjustments.

Step 2. Take measurements

Clamp the larger, flatter jaw on an object to measure the outer diameter or width of the object, or insert the smaller, sharper jaw into the object and slide it to measure the inner diameter and width.

Step 3. Read the size of the scale

The scale written on the caliper can be read as if you were reading a regular ruler. Find the value at the inner end of the jaw section of your caliper.

- The scale will be listed with a unit, usually in cm (centimeters) or in (inches).

- Remember that the inch scale on a caliper is usually an engineer's scale. Each inch is divided into 10 parts (0, 1) or five parts (0, 2). This is different from most rulers, which write 16 or 18 parts per inch.

Step 4. Read the dial size

The hands on the dial indicate additional values for more precise measurements. The units are listed on the face of the dial, usually in units of 0.01 or 0.001 cm or in.

Step 5. Add both values together

Convert those measurements to the same units, then add them together. You may not need to use the most detailed digits in many uses.

For example, a fixed scale shows a size of 5.5 and has units of cm. The hand on the dial indicates 9.2 in units of 0.001 cm, so that measurement is equal to 0.0092 cm. Add the two measurements to get the final measurement, which is 5.5092 cm. You can round it to 5.51 cm, unless you are working on a project that requires very precise measurements

Tips

- Consider purchasing a digital caliper if you have difficulty reading vernier or dial calipers.

- To reduce the risk of errors, place your calipers with your jaw slightly open. Clean the calipers from dust and dirt between the jaws by rubbing rubbing alcohol or mineral material.