- Author Jason Gerald gerald@how-what-advice.com.

- Public 2024-01-19 22:11.

- Last modified 2025-01-23 12:04.

Brazing to join two silver objects, or repairing a crack in a silver object, requires different materials and techniques than most other metal brazing jobs. Even if you already have a work area for brazing ready to go, read or at least skim through that section of this article for things you might need to change before you even start brazing silver.

Some special jobs may require silver (additive metal) solder to join other metals, such as brass or bronze. For such work, you will need to look for specific information about the process, such as information on brazing copper pipes.

Step

Part 1 of 2: Setting up the Work Area

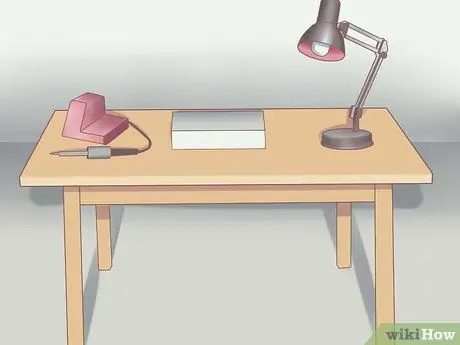

Step 1. Find a block of charcoal brazing base or other suitable work surface

Brazing will not work if too much heat is lost to the air or to the work surface, so you will need to find a special surface with low heat conduction. Charcoal base beams are probably the best choice for brazing silver, as they reflect heat to produce the high temperatures required to work silver. Magnesium base beams or kiln break are common choices, and can withstand more brazing projects than charcoal.

These materials can be purchased at craft supply stores or jewelry supply stores, and are similar in size and shape to regular building bricks

Step 2. Purchase a silver solder

Silver solder is an additive to brazing, made of silver and other metals, designed to hold silver together but melts at lower temperatures. You can buy them in strips in a single container, or you can buy them in sheet or wire and cut them with a wire cutter into 3 mm long strips. Do not try to use lead solder when brazing, as it will usually fail and be difficult to remove.

-

Warning:

Avoid silver solders that contain cadmium, which can cause health problems if the vapor is inhaled.

- If you are repairing a cracked item, you can use a lower purity "easy" silver solder, as it melts at a lower temperature. To hold two objects together, use a "medium" or "hard" silver solder with more silver content, for a stronger bond. Note that there is no single term used by all silver producers; if you use a different brand and want to get the same results as you normally use, look at the percentage of silver content.

Step 3. Use a torch, not a soldering iron

Do not use solder, as it is intended for lower temperature lead soldering and can damage the precious metal. It is better to buy an oxyacytylene torch at a hardware store, preferably one with a flat "chisel tip" rather than one with a sharp tip.

Silver quickly conducts heat from heat-exposed locations. Therefore, using the small tip of the torch can make brazing much slower

Step 4. Choose an all-purpose flux or brazing flux

The melt or "flux" is needed to clean the silver surface and help conduct heat. Flux also helps remove oxidation from the silver surface, which can affect bonding. You can use an all-purpose flux or a "brazing flux" specifically for silver or jewelry.

- "Brazing" fluxes are used to bond at high temperatures, when the surface of a metal object changes itself chemically. Even jewelry makers call this process "soldering or soldering", the correct technical term is actually "brazing or brazing".

- You can use any form of flux. (For example, paste or liquid.)

Step 5. Use a fan for ventilation when needed

Open windows or turn on fans to reduce the amount of steam inhaled, blowing air over the work area and away from you. But keep strong winds away from the object being worked on, because the cold effect can complicate the brazing process.

Step 6. Use tweezers and lead pins

The lead clamp is recommended because it can be used for high temperatures and will not rust and damage the pickle solution described below. Tweezers are used to hold objects made of silver, or of any metal.

Step 7. Take precautions by wearing safety glasses and an apron

Safety glasses are important to protect your eyes from accidental splashes, as you may need to focus your eyes on the joint. Denim or canvas aprons reduce the chances of your clothes getting burned.

Avoid wearing loose or dangling clothing. Roll your arms long and tie back long hair before you start working

Step 8. Prepare the water container

You will need a pot of water to rinse off the silver at the end of the process. Make sure the container is deep enough to dip the silver object in.

Step 9. Heat a container of acid solution or pickle

" Purchase a "pickle," or acid solution used in brazing, which is specifically labeled as suitable for use with silver. Pickles are usually available in powder form. Just before starting brazing, dissolve the powder in water and use a special skillet or "pickle pot" to heat according to the pickle manufacturer's instructions.

- Do not use a skillet, microwave, or oven that you will use again for cooking. Pickles may leave a metallic odor or even some toxic residue. Do not allow the steel to come into contact with the pickle.

- Most pickle solutions can be used or stored for several weeks.

Part 2 of 2: Uniting Silver

Step 1. Clean the silver

Grease removal solutions are recommended for use on oily or heavily processed silver. If oxidation occurs on the surface, you may need to put the silver in the pickle solution before soldering. Alternatively, you can use sandpaper to produce a rough surface for bonding.

Step 2. Apply flux to the joint

Prepare the flux according to the instructions on the package, if it is not ready to use. Use a small brush to apply flux to the silver object. Some people only use flux only when there is solder, to limit the amount of solder flowing into the wrong place. Others apply flux to a larger area to reduce the risk of damage due to limitations, but this is not recommended for beginners.

It is recommended to use a small amount of flux in a separate container, as dipping the brush into its original bottle can cause dirt and affect its function

Step 3. Position the silver components to be joined

Place the two components side by side on top of the base brazing block. Position it exactly where you want it to be, remembering that the two must touch for it to fit together properly.

Step 4. Position the solder on the joint

Use tweezers to pick up a piece of silver and carefully place it at one end of the crack or space between the parts to be joined. Once melted, the solder will be attracted by heat wherever the flux is applied, so you don't have to fill the entire intermediate space right away.

Step 5. Heat the object until the solder melts

Turn on the torch and set the heat to the highest setting. Start by holding the torch about 10 cm from the joint, moving it in small circles to ensure that all the components heat evenly. Move the flame closer and closer to the joint slowly, focusing on the metal object near the solder, not the solder itself. When the solder reaches its melting point, it melts quickly and is attracted to the area of \u200b\u200bthe silver that has been flux coated.

- If one of the objects being joined is thicker than the other, heat the thicker object from behind until the solder begins to melt, then heat the thinner object briefly.

- Use tweezers when necessary to hold the object in place, but place it on the silver tip, away from fire. You may need to hold the small, thin areas of silver to create a hot tub, preventing the thin areas from melting.

Step 6. Immerse the object in water, then immerse it in an acid solution (pickle)

Allow the object to cool for a minute, then cool again with a splash of water. The acid solutions mentioned in the workspace section of this article are the acids used to clean jewelry after soldering. Dip the silver object into this solution using lead tongs, and leave for a few minutes to remove flux and oxidation. Avoid all contact with your skin, clothing, or steel tools, as acid solutions can rust.

Step 7. Rinse the silver

Rinse the silver object that has just been put together with water. Pat dry with a clean cloth. When the process is followed completely, the objects are permanently fused.

Tips

- If using too much stain produces an uneven look, use a file to remove it.

- If the solder doesn't flow as it should, stop it, let it cool, and start again. Clean thoroughly with a cloth and acid solution