- Author Jason Gerald gerald@how-what-advice.com.

- Public 2024-01-19 22:11.

- Last modified 2025-01-23 12:04.

Shoes are one of the important elements in fashion. Given that you've been wearing shoes all day, why not try wearing some cute shoes? Indeed, for those who have not been trained, the manufacturing process is a bit complicated. However, it is not impossible to make it yourself at home. To make shoes, all you have to do is prepare the right materials, make foot prints, cut the shoe parts to size, assemble the parts, and tidy up the design. Once this basic stage is over, you no longer need to rely on brands to polish your appearance. A few embellishments will add to the uniqueness of the shoe, and once you start making it, you'll be instantly hooked.

Step

Part 1 of 4: Preparing the Ingredients

Step 1. Decide what type of shoe you want to make

At the planning stage, you must know the type of shoe to be made. There are a variety of shoes. You can make them, not limited to loafers, sneakers, sandals, boots, and toe shoes. Try to imagine the shoe style that best fits your personality.

- Maybe it will be easier if you also pour these ideas into a sketch. Realizing ideas in the form of illustrations greatly facilitates shoe-making plans.

- If you do not have experience in making shoes, you should choose a simple shape. You can try simple lace-up shoes without the addition of complicated knick-knacks. After all, later you can still add a number of accessories to these shoes.

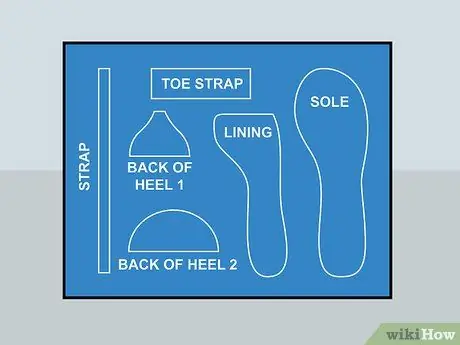

Step 2. Design, search or buy blueprints for your shoes

Before starting to make it, you should prepare an accurate and detailed plan. Avoid making plans while the process is already underway. Shoe making requires high precision and the slightest mistake can spoil the result.

- Simple shoe patterns can also be found on the internet. Search and find some 'way to make it. Even if you don't find it there, at least you'll get some inspiration when designing your shoes.

- Online art like www.etsy.com also seems to sell shoe designs that are richer in knick-knacks.

- Designing your own is only recommended for those of you who have made shoes. If your goal is to design shoes, try making simple shoes using designs that are available for free. This experience will play an important role when you get back to making shoes.

Step 3. Take advantage of the parts of the shoe that are not used

In addition to saving time, this method will give a professional impression on the appearance of the shoe. The sole of the shoe will support the seams. If the soles of your shoes are still in good condition, it's a good idea to save the parts of your shoes that can still be reused. When removing them from old shoes, do so carefully using a scalpel blade.

Step 4. Look for other materials from hardware stores or specialty stores

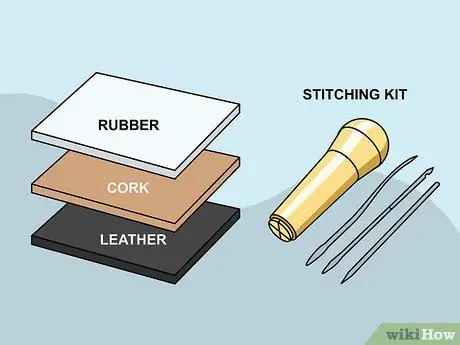

Shoe models sometimes require special materials. So, you no longer need to bother choosing strong leather and fabric materials.

- You will need a sewing tool to make the shoes. If you don't have one, please buy or borrow one.

- Rubber, leather, and fabric are the materials for the chassis or shoe body.

- You are indeed advised to use soles from used shoes or buy them. However, you can also make a waterproof sole using several layers of cork, each layer being about 30 mm thick.

- Don't forget to provide at least twice as much spare material as you need. That way, you won't run out of materials to make a pair of shoes.

Part 2 of 4: Making Foot Prints

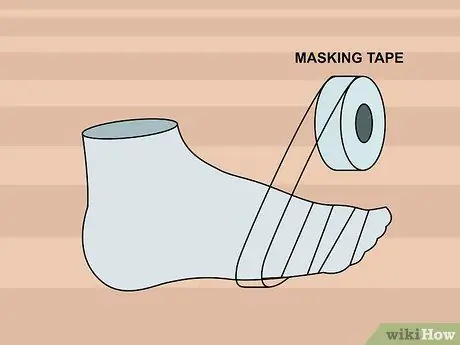

Step 1. Make a foot print

This mold in the shape of a human foot will serve as a guide for the shoemaker as he works. For that, prepare in advance your foot prints. Thus, the results of the shoe will match the size of your foot. Take the box containing the alginate gel and insert your foot, preferably up to the ankle. Let stand for 20 minutes until the gel solidifies. Then, slowly lift your legs.

- Make sure to lift the leg slowly. You certainly don't want to spoil the mold that is starting to solidify, do you?

- It is highly recommended to dip both feet at the same time. You will save a lot of time.

- The advantage at this stage is that you can reuse the mold to make other shoes. Try to store the print in a safe place to avoid the risk of damage.

Step 2. Pour the mold material into its proper place

The foot print is now ready. Please pour the mold material into it. The solidification time can take anywhere from half an hour to an entire night, depending on the type and quality of the material. Be patient. If you have a well-organized plan, this might be a good time to move on to another step.

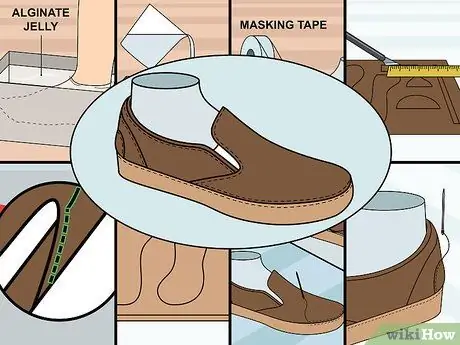

Step 3. Lift and cover the mold with tape

Once the mold has solidified, now is the time to finish. Cover the mold with clear tape to prevent damage. In addition, you can also draw your shoe design directly on the mold.

Draw your design on the mold. Before assembling all the parts, the pattern on the mold may help you imagine the shape of the shoe you want. You don't always have to stick to concrete measures. However, a three-dimensional design of the shoe will show the parts that need sewing

Part 3 of 4: Assembling Shoes

Step 1. Cut the leather and fabric

Prepare your pattern or design. Cut the fabric or leather according to the pattern with a scalpel or scalpel. Use a ruler or protractor to make it easier to cut.

When cutting according to the pattern, increase by at least 2.5 cm. Also add about 1 cm for the parts to be joined. This part will be sewn later

Step 2. Put the parts together and sew them together

Sewing neatly is the most challenging part of making shoes. When sewing, do it slowly and with great care. You may be in a hurry to do this, but the stitches will look bad in the end, and your shoes will look far below expectations. Try sewing all the way to the end of each material. Otherwise, the materials will overlap and the result will be annoying bumps. Please take note of this if you intentionally cut the material slightly larger than necessary to allow for more flexibility in sewing. You don't want the shoe to be too big or too small for the sole to fit in.

Maybe you won't have much trouble sewing the fabric. However, this is not the case with skin. Leather is notoriously tough and you'll have a hard time sewing it neatly. For this reason, it is recommended to punch holes before connecting to other sheets

Step 3. Make eyelets

This hole will be where the rope goes in and out. You should consider it in shoe design. Try to keep the distance between the holes the same (generally no more than 2 cm) and prepare 4-5 eyelets. If you like to make your own, just punch holes with a scalpel knife. However, if you want your shoes to look more professional, there are special eyelets that you can get at certain stores.

Step 4. Cut the sole of the shoe

If you bought ready-made insoles or picked them up from old shoes, there's no need to worry about this stage anymore. However, if you're trying to assemble a shoe with purely homemade materials, you should consider using several sheets of cork. In addition to being waterproof, cork is also a fairly comfortable cushion.

- If the shoe fabric is already sewn, you can use it as a reference when slicing the sole or cork. However, you still have to rely on the existing print sizes.

- Foot prints should be easy to carry everywhere. Cut the sole slightly larger than the cork sheet to allow some space around the mold. Thus, your feet can breathe more freely.

- If you want more cushioning and more height, you can add a second or third layer of cork to the sole. Simply cut the cork with the exact same shape and size, then glue it with glue.

- After applying the glue, leave the cork sole for a few moments so that the adhesion is stronger.

- To make a heel, you can add an extra layer to the back third of the sole.

Step 5. Sew and glue the shoe layers

You will not succeed in sewing the fabric on the sole. It is recommended to use special shoe glue to glue the fabric to the sole. Apply glue slowly and evenly. This will maximize the waterproof coating on the shoe and make it sturdy. If your blueprint suggests additional stitches, follow those suggestions.

- Insert the foot print into the shoe as you put the fabric and sole together. The mold will be a very helpful reference when you complete the challenging sewing process.

- If you have mastered the different types of stitches, feel free to play the stitch style. The stitching style can be an aesthetically appealing element. If you have bigger guts, feel free to try unique stitch patterns as long as they don't interfere with practicality.

Step 6. Cut off excess fabric and add where needed

Now your shoes are relatively ready. Add shoelaces and thread them through the holes. To make the shoes look beautiful, you can cut off the excess fabric. If there are some untidy seams, you can add a new layer of leather or fabric to cover them. Once the shoe body is ready, you can think about how to add an aesthetic element to it.

Step 7. Repeat the process for the other side of the shoe

The assumption is, you make two shoes to be worn at the same time. After the basics of making the first shoe are complete, it is time to make the second shoe. Remember, you are not making a copy, but the reverse of the first shoe. Try to make the second shoe look exactly the same as the first. All the parts you made in the first shoe will look bad if you don't copy it exactly in the second shoe.

If making the first cleavage feels overwhelming, you will enjoy the process of making the second cleavage even more

Part 4 of 4: Adding the Finishing Touches to Your Work

Step 1. Use a special spray to make your shoes waterproof

Shoes made of leather will automatically be waterproof. However, of course you want to be absolutely sure that not a single drop of water will get into the shoe. Buy a regular, inexpensive spray sealant and spray it all over the shoe. It's worth trying, especially if you live in an area that gets a lot of water.

Step 2. Add a decorative touch to your shoes

You've gone to great lengths to make something yourself. Of course you want to add your own style to it. You have plenty of opportunities to do this even after the shoe is finished.

- You can add style to your shoes by drawing on the leather and embedding a new style design.

- There are so many ways to make your shoes look stylish. Please look for some ideas on the internet when you need inspiration.

Step 3. Put on your shoes and check for comfort

Now your cool shoes are done. This is the time to try it. Walk down a corridor or a street and feel your shoes. Are you comfortable wearing it? Won't your shoes get wet if you accidentally walk through puddles? If it's your first time making shoes, these problems are fairly common. If the end result is not satisfactory, you are now more qualified to make a new pair of shoes.

If the cause of the discomfort is the insole, you can buy gel insoles (such as Dr. Scholl's) to give your feet enough cushioning

Tips

- It is highly recommended to make shoes at the same time. In addition to saving time, your shoes will look much more alike if they are done in close proximity.

- Some stitches can only be done by those who are experienced and have high flying hours. Try experimenting with sewing on several pieces of fabric until you get the hang of it.