- Author Jason Gerald gerald@how-what-advice.com.

- Public 2023-12-16 10:50.

- Last modified 2025-01-23 12:04.

So you've designed the circuit and it's ready to go. You have used the help of computer simulation and the circuit works great. Only one thing is left! You need to build a printed circuit board so you can see it in action! Whether your circuit is a project for your school/college or is a final electronics piece of a professional product for your company, applying your circuit to a PCB will give it a much better appearance, as well as give you an idea of how the final product will look!

This article will show you the different ways you can create a printed circuit board (PCB) for an electrical/electronic circuit using a variety of different methods, which suit small to large circuits.

Step

Step 1. Choose a method used to make the PCB

Your choice will usually be based on the availability of the materials required by the method, the technical difficulty of the method or the quality of the PCB you want to obtain. This is a brief summary of the different methods and their main features that will help you decide:

- Acid etching method: this method requires a very high level of safety, the availability of many materials, such as the etch, and the process is rather slow. The quality of the PCB you get varies according to the material you use, but in general, it's a good way to scale circuit complexity from simple to medium. Circuits consisting of tighter paths and thinner wires will usually use the other method.

- UV etching method: this method is used to transpose from your PCB layout onto the PCB board and requires more expensive materials that probably won't be available anywhere else. However, the steps are relatively simple and can result in finer and more complicated circuit layouts.

- Mechanical etching/tracing method: this method requires special machines that will mechanically etch clean unneeded copper from the board or create blank separator paths between wires. This can be an expensive method if you plan to buy one of these machines and usually, renting one requires the availability of a repair shop nearby. However, this method is good if you need to make a large number of circuit copies and can also make a smooth PCB.

-

Laser etching method: this is usually found in large production capacity companies, but can also be found in some universities. The concept is similar to mechanical etching, except that a LASER beam is used to etch the board. It's usually hard to get a machine like this, but if your local university is one of the lucky ones to have one, you can use their facilities, if they allow.

Create Printed Circuit Boards Step 2 Step 2. Create a PCB Layout of your circuit

This is usually done by converting your schematic diagram of your circuit into a PCB layout using PCB layout builder software. There are many open source software packages for creating and designing PCB layouts, some of which are listed here for initial information:

- PCB

- Liquid PCB

- ShortCut

Create Printed Circuit Boards Step 3 Step 3. Make sure you have gathered all the required materials based on the method you choose

Step 4. Draw a circuit layout on a copper-clad board

This can only be done in the first two ways. More details can be found in the details section of the method you choose.

Create Printed Circuit Boards Step 5 Step 5. Etch the board

Check out the details section for how to etch a board. This process is to remove unneeded copper from the board, the layout of the final circuit.

Create Printed Circuit Boards Step 6 Step 6. Drill the mounting points

Drilling machines used are usually special machines designed specifically for this purpose. However, with a few adjustments, an ordinary drilling machine will work at home.

Create Printed Circuit Boards Step 7 Step 7. Install and solder the electronic components on the board

Method 1 of 2: Specific steps for acid etching

Create Printed Circuit Boards Step 8 Step 1. Choose your etching acid

Ferric chloride is a common choice for an etchant. However, you can use ammonium persulfate crystals or other chemical solutions. Whatever the choice of chemical etcher, it will always be a hazardous material. So in addition to following the general safety precautions mentioned in this article, you should also read and follow the other safety precautions that come with the etcher.

Create Printed Circuit Boards Step 9 Step 2. Describe the PCB layout

For acid etching, you need to draw the circuit using an anti-etc. Custom markers can be found easily for this particular purpose, if you plan to draw them by hand (not suitable for medium to large sized circuits). However, laser printing inks are the most commonly used. The steps for using a laser printer to illustrate a circuit layout are as follows:

- Print the PCB layout on a glossy paper. You should make sure that the circuit is mirrored before doing so (most PCB layout programs have this as an option at the time of printing). It only works with a laser printer.

- Place the glossy side, with the print on it, facing the copper.

- Iron the paper using a regular clothes iron. The time it takes to do this depends on the type of paper and ink used.

- Soak the board and paper in hot water for a few minutes (up to 10 minutes).

-

Remove the paper. If certain areas seem difficult to remove, you can try soaking them longer. If all goes well, you should have a copper board with your PCB mount and signal lines drawn in black laser printer ink.

Create Printed Circuit Boards Step 10 Step 3. Prepare the etching acid

Depending on the etching acid you choose, there may be additional clues. For example, some types of acid that are crystallized need to be dissolved in hot water first, but there are other etchants that are ready to use.

Create Printed Circuit Boards Step 11 Step 4. Soak the board in acid

Create Printed Circuit Boards Step 12 Step 5. Make sure to stir it every 3-5 minutes

Create Printed Circuit Boards Step 13 Step 6. Take the board out and wash it until all the unneeded copper is removed from the board

Create Printed Circuit Boards Step 14 Step 7. Remove the image insulation material used

There are special solvents available for almost all types of image insulation materials used in PCB layout drawing. However, if you can't get your hands on these materials, you can always use sandpaper (the smooth type).

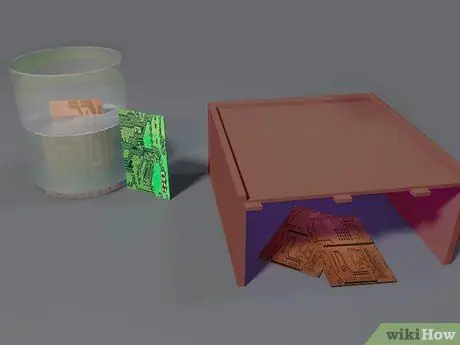

Method 2 of 2: Specific steps for transposition with Ultra-Violet

Step 1. To apply this method, you need a PCB board laminated with a photosensitive layer (positive or negative), a UV insulator and a transparent sheet and distilled water

Chances are you can find PCB boards ready to use (they are generally coated with a piece of nylon cloth) or photosensitive spray to apply to the copper side of a regular blank PCB board. Don't forget to also purchase a photorevelator that matches the photo spray or photosensitive coating of the PCB.

Create Printed Circuit Boards Step 15 Step 2. With a laser printer, draw the PCB layout on a transparent sheet, in either positive or negative mode, according to the photosensitive layer on the board

Create Printed Circuit Boards Step 16 Step 3. Cover the copper side of the board with a printed transparent sheet

Create Printed Circuit Boards Step 17 Step 4. Place the board in the UV isolator machine/chamber

Step 5. Turn on the UV machine

This machine will irradiate your board with UV light for a set amount of time. Most UV insulators are equipped with an adjustable timer. Generally, 15 to 20 minutes is sufficient.

Step 6. Once done, remove the board from the UV insulator

Clean the copper side of the board with a photorevelator, then gently wash the leveled PCB board with distilled water before placing it in the acid wash. The parts that are destroyed by UV irradiation will be etched with acid.

Step 7. The further steps to follow are described in the specific steps for acid etching, steps 3 to 7

Warning

-

If you use the acid etching method, you need the following precautions:

- Always store your acid in a cool, safe place. Use a container made of glass.

- Label your acid and store it in a place where children cannot reach it.

- Do not flush used acid down the drain at home. Instead, save them and when you have enough of them, take them to a recycling center/hazardous waste disposal facility in your area.

- Use gloves and a mask when working with acid etchants.

- Be careful when mixing and stirring the acid. Do not use objects made of metal and do not place the container on the edge of the table.

- When irradiating your PCB with UV, be careful not to make direct visual contact with the part of the insulator/room that generates UV light or wear special UV-protective goggles. If you must inspect the PCB during the process, it is best to stop the machine before opening it.

-