- Author Jason Gerald gerald@how-what-advice.com.

- Public 2023-12-16 10:50.

- Last modified 2025-01-23 12:04.

Making a longboard for skateboarding is usually cheaper than buying it. What's more, making your own unique board is sure to be a lot of fun. You'll need some wood-cutting skills, some carpentry tools, a little creativity, and a lot of motivation to make your own boards. Ask a friend, parent, or staff at a skateboard shop for help if you need it.

Step

Part 1 of 5: Choosing Your Components

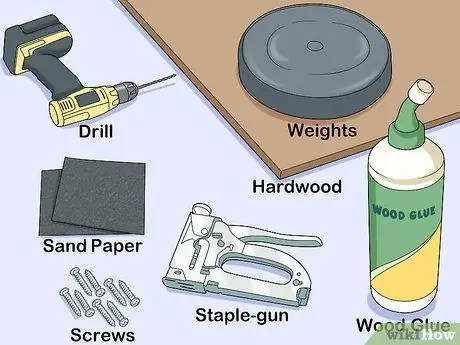

Step 1. Gather the materials for the deck

What you will need:

- Plywood (plywood) or hardwood for making decks; 2-3

- Wood glue or other strong adhesive

- Coarse and fine sandpaper

- 8 small screws to attach the truck to the deck. Four screws for each truck. The length of the screws should be long enough to securely attach the truck to the board, but not so long that it extends through the board. Uniform the width of the hole size on the truck.

- Screws or staple gun (high-power staple gun) to help secure the board as you bend it. The number of screws / staples is very dependent on the size of the board and the quality of the pressing mechanism. Screws may not be needed if you are using a board press. But the screws will make the deck tighter if you combine them with weights or clamps (clamps).

- Drill

- ballast load

- Saws for cutting decks

- Polyurethane or fiberglass resin polish, hardener, and fabric

- A large piece of paper and a pencil to draw the board design.

- Grip tape (to make your feet grip the top of the board)

Step 2. Choose your wood

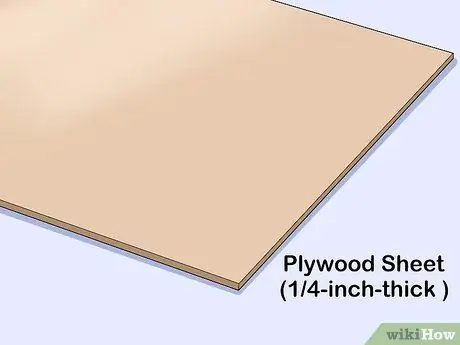

For inexpensive boards, use 2-3 pieces of plywood 0.6 cm thick or 4-6 pieces 0.3 cm thick. Alternatively, use 7-9 sheets one millimeter thick each. Use screws or wood glue to join these pieces of wood into a longboard deck. The number of pieces of wood you use will depend on the flexibility you want: the more layers of wood you have, the stiffer the board will be. You can also buy an unstressed deck and make a longboard out of that shape.

- If you have the time or money, try to find high-quality wood. Bamboo, Birch, White Ash, and Maple are popular choices, and each has its own advantages. Bamboo is the strongest of the woods.

- Each piece of wood should be 25 cm wide and 100 cm long, or longer if you want a longer board. You must first have a basic idea of the shape of the board you want before you start making it. But remember, you can always cut the wood to size.

- Don't go to a lumber shop: the wood is usually dry there, and it's better for construction than for driving. Real wood storage is the best choice. In fact, you can use any hardwood. Even the rest of the plywood for the floor.

Step 3. Choose your adhesive

Find a good, flexible wood glue, or an epoxy or resin. You can find these products at most hardware or hardware stores. Adhesive serves to glue layers of plywood. So if you have cheap wood glue, you will have cheap boards.

Step 4. Choose your truck

A truck is a piece of metal that attaches the wheels to the board and allows the longboard to turn when you lean over. Selection of the right truck is very important in controlling the longboard speed. You can choose Reverse Kingpin Trucks, unless the board has a tail and you plan to do an ollie (the movement of lifting the board up by tapping the tail on the ground). Standard Kingpin provides better hit, while Reverse provides better stability and turning response.

A number of longboard trucks have Double Kingpin, so they can do a tighter carve, but have to sacrifice a little stability

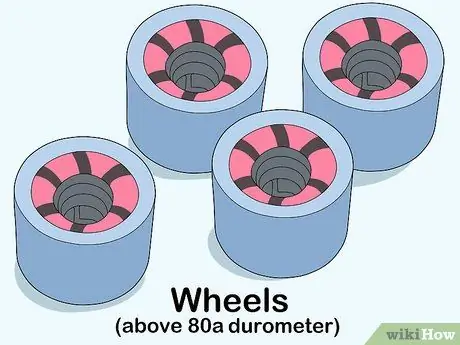

Step 5. Choose your wheel

The harder the wheel, the more it will slide. If you want to be able to go left and right, choose a wheel with a higher (harder) durometer. Wheels that can slide well usually have a durometer above 80a. Softer wheels will grip more and make corners better.

Step 6. Choose your bearings

Bearing is inserted into the wheel and serves to make the wheel turn smoothly. The price is quite high, depending on the quality you want. Ceramic bearings are good, but they can cost more than one million rupiah. A set of steel bearings can be purchased at a price of approximately 200 thousand rupiah. For example, try looking at Bones Reds or Seismic Tektons for the lowest bearing levels.

Part 2 of 5: Gluing and Forming the Deck

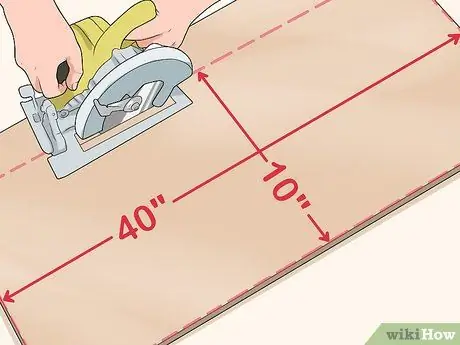

Step 1. Cut the plywood (or hardwood) to size

Cut the wood into strips that are 25 cm wide and 100 cm long, slightly longer than you want your plank to be. Leave longer pieces for longer boards or shorter pieces for shorter boards. Don't worry about shaping the planks: you only need rectangular planks of plywood at this point. You'll cut out the shape of your board once you've pressed the pieces together into one solid deck.

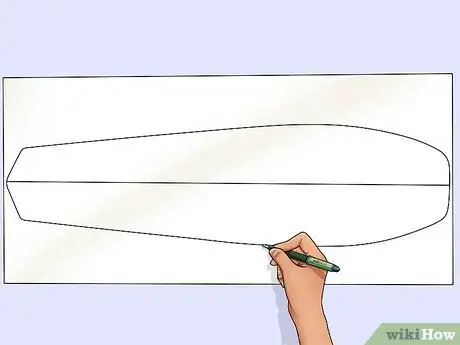

Step 2. Draw the shape of your board

On the paper, draw a line that is the same length as the board you want. This line will be the center of your board. Now draw the shape of your board because the shape will be drawn from these lines. If you want a symmetrical plank shape, draw only half of the deck, then use the same lines to cut both sides. Consider how you want to use your longboard: longer boards (over 100-150 cm) are better at building strength on long straights; shorter boards tend to be easier to carry and are better at making sharp, fast turns; Cruising boards tend to be wider and carving boards tend to be slimmer.

If this is your first board, keep things simple. Draw a curved line on the front and try to line it with precision and width, as you will be driving the board in this part. The widest part of the board is 1/3 down from the front end of the board (nose)

Step 3. Use a pencil to trace the shape of your plank onto the top of the wood

Press all the wood together by applying pressure and adhesive. Let the pressed wood dry and then draw the shape. Trace carefully and make sure you draw the deck the way you want it. Watch for defects in the wood. Make sure that each half of the board is equally symmetrical, unless you really want it to be asymmetrical.

Step 4. Make holes around the outline of the board drawing

You will drill screws through these holes to help glue the wood together. Therefore, try to make the hole a little smaller than the screw. Again, the number of screws (as well as the holes) will depend largely on the size of your board, so there's no exact number you should use. Try to evenly space the screw points around the shape of the board. Determine which points in your design may require additional support to be glued together. For example, parts of the board that stick out or parts of the board that are pulled into the middle.

- Keep the pieces of plywood or hardwood stacked evenly and hold them together so they don't move. Make holes that go straight through the wood using a drill and make sure you don't drill through the area that will be the deck. The holes are drilled at a distance of about 2.5 cm from the drawing line of the board.

- It is better if the wood is clamped / clamped first before the holes are drilled. The screws are drilled directly into the wood. Be careful not to drill into the shape of the deck.

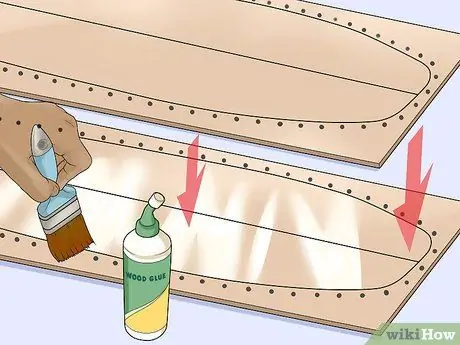

Step 5. Glue the pieces of wood together

Mix the adhesive, then use a brush to apply a thick layer of adhesive to the forward-facing side of the piece of wood. Then slowly put the pieces of wood back together. Make sure the holes that have not been screwed are still at the top.

Be sure to protect the floor. The pressure of gluing the boards will cause the glue to ooze out of the edges of the wood and the holes that haven't been screwed in. You definitely don't want the glue to spill on the floor

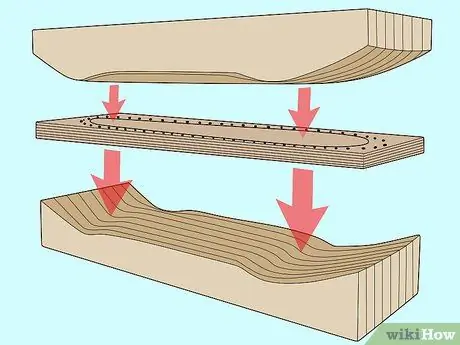

Step 6. Shape the board

Stack the plywood pieces with the smooth side of one side (which will be the top surface of the longboard) on the bottom. Arrange the wood so that each end of the plank rests against something, and the middle hangs freely.

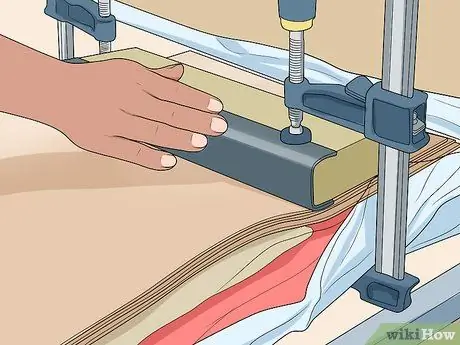

Step 7. Place the weights on the plank

Place the weights on the pile of wood, just around the widest part of the plank. You'll want your board to bend slightly up in the middle. That way, when you stand on it, the board is level. This procedure is more like a work of art. So, put some weight on it until you are happy with the result. For best results, make small arches. Leave the plank under weight until the wood follows the curve snugly.

Consider using strong clamps/clamps instead of weights. Pin the center of the board until it sinks under the edges of the front and back decks

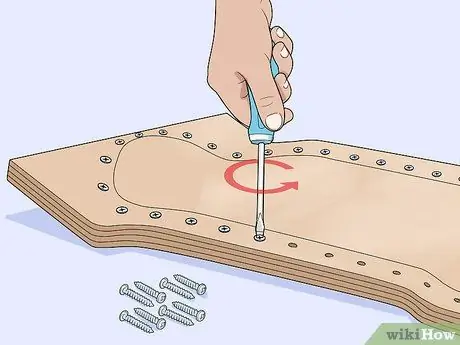

Step 8. Insert one screw into the hole near the nose of your board

Then put the weight back on it or re-clamp the deck. If you are satisfied with the bend, screw in all the holes around the board. Leave the part between the lines without applying the adhesive.

Step 9. Double-check the curve to make sure you're satisfied

When you are sure, wait for the adhesive to work optimally. Follow the directions on the bottle.

Step 10. Remove the screws

Step 11. Consider using a board press to form the deck

Board presses are a lot more expensive than regular adhesives, but can be a wise investment if you plan to make a lot of boards. There are two types of board presses: coffin presses and vacuum presses.

- Coffin press: a coffin press is two 2x4s that clamp the edges of one sheet of plywood, with the other 2x4's clamping the center of another sheet of plywood. These plywood sheets are then connected with screws and nuts with the 2x4 facing inward. The boards (all layers glued together) are placed on two 2x4s. Then place the top of the coffin press on the board, screwing it down to the size of concave you want. Wait about 24 hours for the glue to dry, then cut the boards into shape, and you're decked out!

- Vacuum press: When you load the plywood sheets, they are all cut to shape and glued together. The vacuum press sucks out all the air while pressing the plywood sheets into a shape you can work with. Wait 24 hours with the sheets still in the vacuum press, then it becomes a deck. You can buy a vacuum press online.

Part 3 of 5: Completing the Deck

Step 1. Cut the shape into a board

Take one of the pieces of plywood, and find the nicest and smoothest side. This will be the bottom of the board.

- Measure from the edge to find the midpoint of the board. Draw a line down the center of the board, from front to back.

- Trace also the edges of your pattern sample. Hold the sample pattern with your hands, tongs, or a weight.

- Turn the board over and repeat on the other side.

- Your design is ready on your board. Remove your mold from the plywood and make sure you like the shape.

Step 2. Smooth everything with sandpaper

Make sure the board is smooth and clean of scratches.

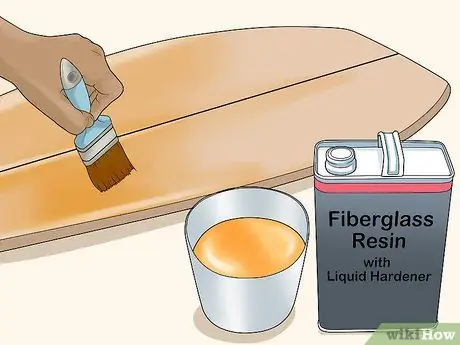

Step 3. Cover the surface of the board with a coat of polyurethane polish or fiberglass resin

Both will protect the paint from scratches. Browse various building and skateboard shops to compare prices and check what's available in your area.

- If you are using fiberglass resin: First, mix the fiberglass resin with the hardening liquid according to the proportions. Then spread the fiberglass cloth over the painted side. Apply the resin evenly over the entire board using a brush. Work quickly and effectively, as the fiberglass begins to harden after about 15 minutes. Once done, let it sit for 3-4 hours.

- If you are using a polyurethane polish: Apply the polish evenly to the entire surface of the board using a brush. Make sure the fabric is smooth. Once you're done, let the paint dry for 3-4 hours before you move on to making your board.

Part 4 of 5: Decorating the Board

Step 1. Sand the board one last time using a very fine type of sandpaper

Now, you can add any design you want, using waterproof paint or marker.

Step 2. Consider painting your board

You can just leave your board as it is with its natural wood appearance. But your board will be unique if it is painted or added with other decorations. Use electrical tape or prints to mark your designs. The bottom of the deck should be painted.

- Use spray paint. Make a print out of paper or cardboard, choose the colors, and spray-paint the design on the smooth underside of the board. Let the paint dry before you touch it or ride the board.

- Use regular acrylic paint. Sketch the design and paint between the lines; paint whatever you like. Allow 20-60 minutes for the paint to dry after you decorate the board.

- Using wood stain paint (water-based car). To create grooves with various color variations, use three coats of paint for the dark areas and one coat of paint for the lighter areas. After the paint dries, remove the tape.

- Use permanent marker. Your design will probably have less color and be more brittle than if you used paint. But you'll feel more in control when you draw on the board with a marker.

Step 3. Apply a polyurethane or fiberglass resin polish as a final coat

This will be your design's cover layer on the bottom of the board. The polish or resin should be a clear color, so that your design can still be seen through the protective layer.

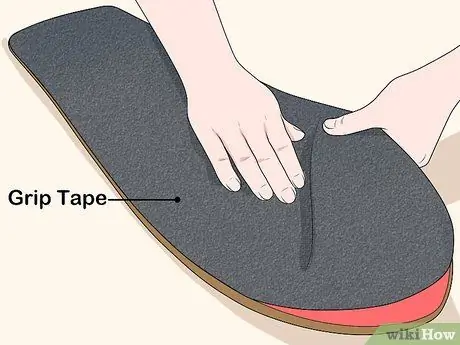

Step 4. Cover the top of the board with grip tape

Buy a large roll of grip tape that will cover your entire board. This tape will help keep your feet on the board when traveling at high speeds. Stick it carefully on the deck, like a large sticker. Remove excess tape residue with a razor or knife cutter. The design is up to you:

- Cover the entire surface with grip tape. This is the easiest method, and will look like the top of a standard longboard.

- Cut and create designs from grip tape. Make sure you cover enough of the surface of the board, so your feet can grip it easily. In general, your board should have more grip tape than the bare wood.

- Paint the board and apply clear colored grip tape over it to show your design. The clear grip tape may look blurry, but the colors and the general idea of your design will shine through.

Step 5. Consider using board wax instead of grip tape if you want to ride barefoot

Use surfboard wax on the surface of the longboard if you plan to ride it barefoot more often. Remember that you will have to reapply the wax when it has worn off.

Part 5 of 5: Installing Trucks, Wheels and Bearings

Step 1. Install the bearing in the wheel

To do this, take the bearings and press them into each wheel. You can't push it too far; there is little space that limits its placement. Insert a bearing into each of the four wheels.

Step 2. Install the wheels on the truck

Just slip the wheel/bearing combination into the truck, with the concave side of the wheel facing out (if the wheel has a concave). Tighten the wheel / bearing on the truck using the nuts provided. The nut is tightened sufficiently, so as not to interfere with the smooth rotation of the wheel. But also don't let it get too tight, so that the wheels come off while sliding.

Step 3. Make a hole for the truck using a drill

Make sure the holes are perpendicular. Otherwise, the truck will not be installed properly.

Step 4. Install the truck and wheels on the deck

You will need a truck spacer and a truck to do this. Place a divider between the truck and the deck. When installing the truck mount, make sure the bolt to tighten is facing the nose of the board at the front and the bolt to loosen is facing the tail board at the rear. The purpose of adjusting the bolts in opposite directions is to make sure you turn in the right direction when you lean. Tighten the truck and the splitter on the deck using the 4 bolts on each truck.

Step 5. Test your new board

Once you've installed the bearings, wheels, and truck on the deck, your board is ready to roll. Stand on the plank to make sure it can support your weight. If the board doesn't break under your weight, try riding it on the pavement. Make sure you double-check all parts of the board-bearings, wheels, truck, deck-before you take it for a ride on busy roads or trails.

Tips

- Make sure the surface you're standing on has plenty of friction, so you don't fall.

- Be creative. This is your board, so it can be anything you want. Even so, be very careful too, because it is precision here that makes the board beautiful. Do it twice the precision if possible.

- Try to keep the nose section precise and wide, as you will be driving the board in this section. The widest part of the board is 1/3 down from the nose.

Warning

- Be careful not to split the board. It takes a few tries to get a good board.

- Have fun and be careful when you ride the board.

- Always wear the correct safety equipment: helmet, knee guards and wrist guards.

- Always wear special gloves for sliding if you do acrobatic movements.