- Author Jason Gerald gerald@how-what-advice.com.

- Public 2023-12-16 10:50.

- Last modified 2025-01-23 12:04.

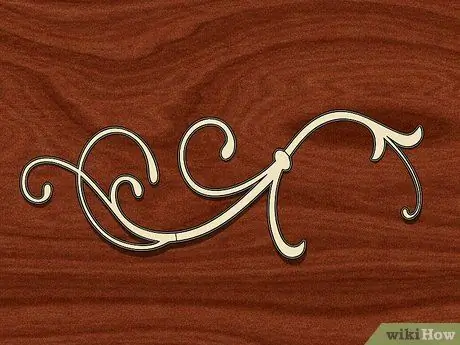

Inlay contrasting materials add an eye-catching element to any wooden item, such as a picture frame, jewelry box, or piece of furniture. The best way to master this technique is to first inlay straight lines and then progress to circular or oval shapes, before tackling more complex designs. The simple methods detailed below require no special tools, while the complex instructions will allow you to create intricate and beautiful designs once you have the tools and woodworking experience.

Step

Method 1 of 2: Simple Inlay

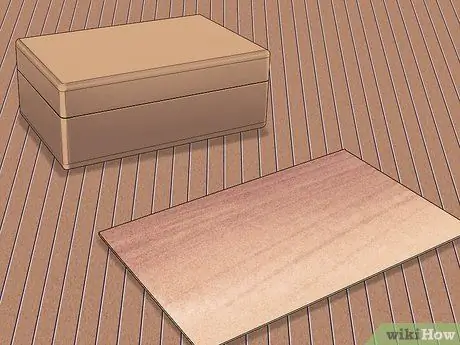

Step 1. Choose your base and inlay

Choose a wooden object to decorate, such as a piece of furniture, a box, a guitar neck, or a practice block. For your inlay, you can use a thin flat material, such as wood lacquer, oyster shell, or a small piece of bone or ivory.

One dark material and one bright material will create a pleasant contrast and make the gaps between them less visible

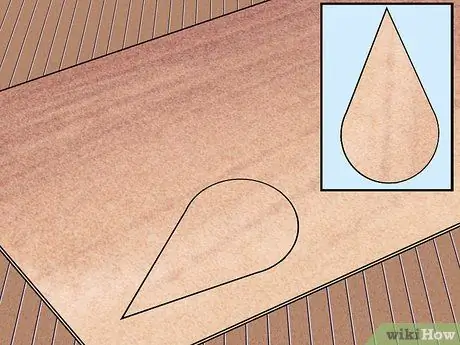

Step 2. Cut the inlay into simple shapes

You may already have a piece in the size or shape you want. If not, saw off to a simple shape.

- Wear a dust mask whenever you are sawing oyster shells or other materials that produce sharp and harmful dust.

- Any type of sharp, well-maintained saw can cut oyster shells, but you should periodically dip the oyster shells in water to prevent burn marks.

- Limit yourself to simple free-cuts or plotting small geometric designs. Check out the instructions for elaborate designs if you want something more ornate.

Step 3. Temporarily glue the pieces to the base

You can use double-sided tape or glue sticks that take a long time to harden. This will keep the inlay piece stable for you to mark and cut.

- Or, you can mark your cut onto tracing paper and tape it to the base.

- In particular, simple pieces that take only a little time to mark can be held in place by hand if they are large enough to hold without injuring yourself.

Step 4. Mark the inlay onto the wooden base

Use a pencil to mark the outline of your inlay onto the wood. It is better to make the wrong design too small than too big.

Step 5. Gradually cut into the marked lines with a sharp knife

Using an x-acto knife or other hobby knife, cut into the marked lines.

- Start by making small holes in the wood to make grooves. Once the groove is made, you can continue cutting downwards with less risk of the blade slipping through the wood grain.

- Cut the wood as deep as necessary just for the inlay pieces to fit. If it's a little shallow, you can sand the cut. If it's too deep, you'll need to sand the entire surface of the wood to make it even.

Step 6. Remove the inlay and cut the wood underneath

Now that the edges are ready, you can create niches in which the inlay will be installed. Be careful not to cut too deep.

- Small, simple designs can be sculpted using hand tools such as a router plane, chisel, or sharp knife. Larger or more complex recesses are quicker and easier to create with a power tool such as a Dremel, laminate trimmer, or large trimmer.

- If you are using double-sided tape, you may need to wiggle a putty knife or other wide, flat blade under the decorative object to pull it off the base.

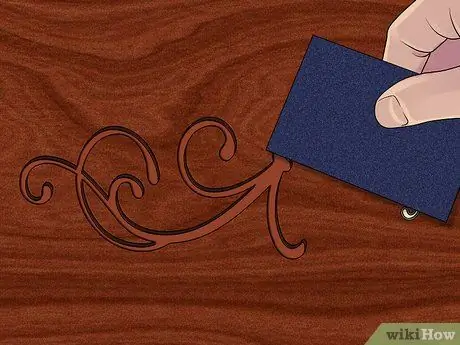

Step 7. Smooth the sculpted area

Use a small piece of sandpaper to smooth out the base and edges after most of the wood has been removed.

Step 8. Make sure the pieces fit

Ideally, it fits snugly, so if you can't really force it in, you may be able to knock it in after applying the glue.

- Optionally, you can sand the edges of the inlay to create beveled edges, narrower at the bottom than the top. This makes installation easier without exposing gaps.

- It's rare that your piece is so firmly attached that it can't be removed again. In this case you can apply a thin layer of transparent glue over the inlay for added strength and leave it firmly attached.

Step 9. Mix the sawdust into the glue

Mixing the sawdust well into the glue covers the gaps to make it look like the original material.

Use wood glue to set the wood on the wood, or epoxy if you are setting other materials

Step 10. Apply glue liberally and stick

Cover the recesses and base of the inlay with glue and glue the pieces together. Gently tap with the tool handle to push into the bottom of the recess.

Step 11. Make the final adjustments

Wipe off excess glue, but not glue in the gap between the two materials. If the inlay sticks out a bit, sand it flat against the wood base.

Use 220 or finer sandpaper to keep the inlay nice and polished

Method 2 of 2: Crafting Complex Designs

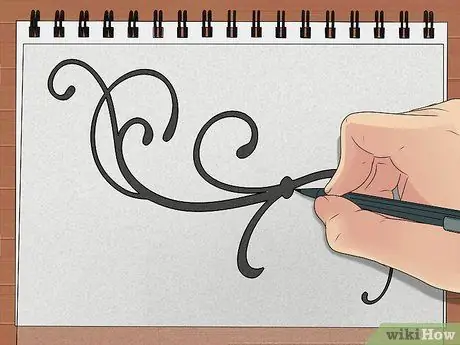

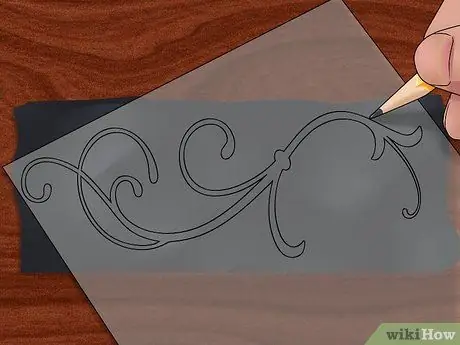

Step 1. Make your plan

Place translucent tracing paper on your computer monitor or art book to draw lines from the reference image, or draw your own directly onto the tracing paper.

- Avoid small pieces and tricky lines until you become a skilled carver.

- Consider the materials you will use for each section. Use some inlay material for better contrast and aesthetics.

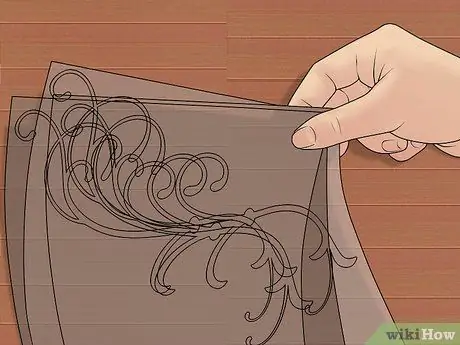

Step 2. Make several copies of your design

Cutting each piece of your inlay from the individual sheet of tracing paper ensures that you will get pieces of the right size. Leave at least one "master draft" sheet that won't be cut at all.

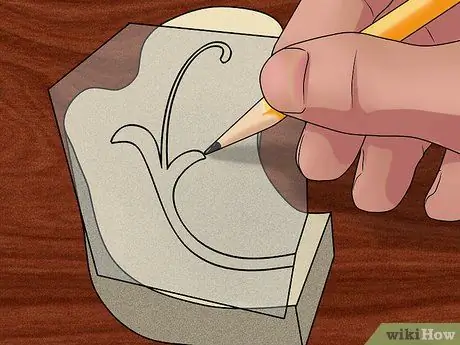

Step 3. Glue the design onto the wood

Place the main draft sheet on top of the carbon paper and ink again to mark the design onto the wood you want to inlay.

- You may also want to include some "reference marks" in the design to help you adjust when inlay.

- If you don't have carbon paper, cut one of your copies and tape it in place, then tape the perimeter to the wood. You will need to cut each section and tape to a larger design, shaving around the edges as well.

Step 4. Cut each piece of paper from a separate copy

Cutting them all from one notch will result in a cut that is too small. Number each on the surface and on the main design sheet in the order in which the inlay will be performed. Start with the furthest background elements and work your way up to the foreground.

Cut out the larger pieces of the edge that will fit under the other pieces to create an overlapping effect. You can even cut off the entire "implied" part, such as a leaf that will be half hidden behind another leaf

Step 5. Make a sample from fiberboard (optional)

To ensure a precise cut pattern, you can plaster your pattern onto medium density fiberboard (MDF) and cut it using a table saw, decorative saw, circular saw, or jigsaw with the proper technique:

- Only use a laminate or carbide blade or a carbide drill bit to cut the fiberboard.

- Use eye protection.

- Clean the table saw thoroughly to remove debris that could cause an ugly cut.

- Clamp the fiberboard and scrape it with a cutter knife before using a circular saw or jigsaw.

Step 6. Cut the first piece of inlay material

Plaster a sample of fiberboard or paper clippings onto wood varnish or other inlay material. Draw a pattern on it with a pencil, or cut straight around it for materials that a pencil won't mark.

- Use an x-acto knife or other cutter knife to varnish wood. Previously scratch a little to avoid the knife drifting along the grain of the wood rather than the desired pattern.

- For materials that cannot be cut with a knife, use a decorative saw or other accurate saw. Always wear a breathing mask and a fan blowing away from you when generating this kind of dust.

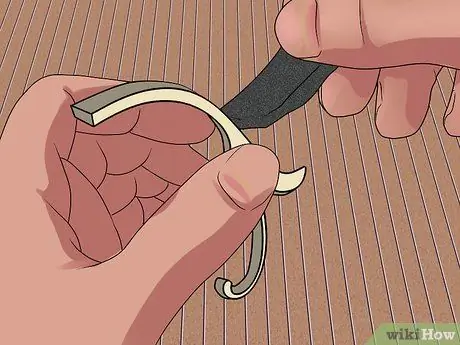

Step 7. Sand or file the edges until smooth

Make the cut side smooth and even so that it matches the other cuts and the base material.

Step 8. Temporarily glue the piece or sample to the base

Glue the piece to the double-sided tape and trace it with your fingernail to ensure that the tape is completely adhered and smooth. Peel off the paper layer and stick it to the incised wooden base.

- Alternatively, you can use glue that has been hardened for a long time. This will hold it firmly but not permanently attach to the base while you cut the line.

- If your double-sided tape is too weak, try finding a type called "turner plaster" at a craft store.

- Once it's in place, use a cutter knife to cut off any excess plaster so you can see what you're doing.

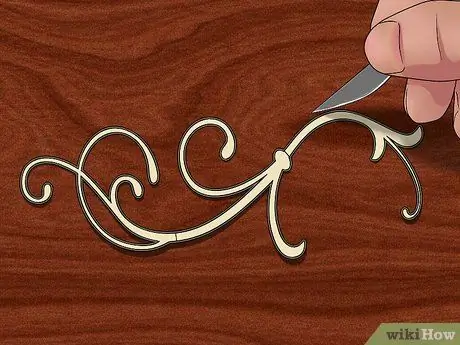

Step 9. Cut gently around the cut, then remove the inlay

Use your cutter knife to lightly scrape the cut line, then deepen the groove a little. Use a thin, flat putty knife to wiggle loose pieces of plaster or glue. Be careful not to break it or damage the base.

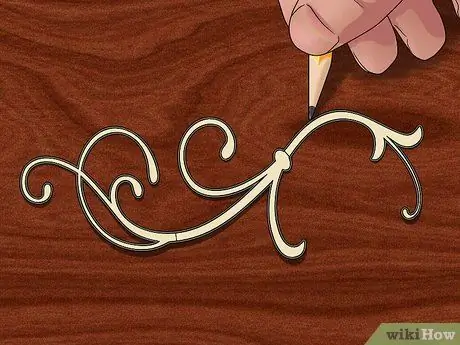

Step 10. Draw a groove to make it look clearer

Use a pencil or chalk to make the groove clearly visible, then erase the outline around it. Delete across the path, not following it.

Remember not to erase the marks you need to place the next plates

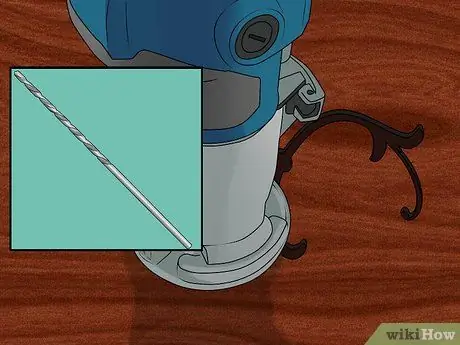

Step 11. Prepare your cutting tools

A full power special saw is the most stable way to create a niche for your inlay design. If not available, use a Dremel with the addition of a special saw, or a special saw that is lighter but less stable like a laminate trimmer.

Set the depth of your cutting tool slightly less than the height of your inlay plate - one millimeter difference

Step 12. Trim most of the recesses with a 3.0 or 3.5 mm drill bit

Trim the wood base to a certain depth, but stay away from the outline. This requires a more precise drill bit.

Step 13. Cut to the edge using a 1.5 or 1.6 mm drill bit

Change the drill bit to a smaller size and very carefully approach the outline of the recess. Stop as soon as you reach the groove.

- When you stop seeing dust and rough frayed wood appear on the surface, stop immediately. You have reached the path you created.

- This is much easier to see with magnifying glasses.

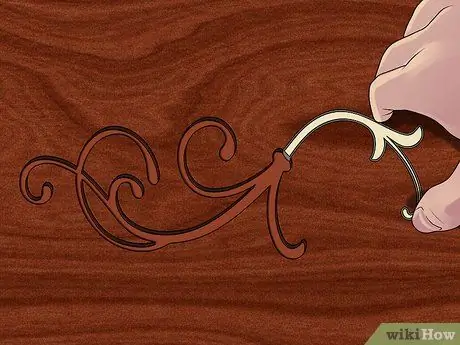

Step 14. Glue the plate inside

Apply plenty of glue to the bottom of the recess and use a brush to make sure it covers the sides as well.

- Use wood glue for varnish. Use an epoxy or other special strong adhesive for different inlay materials.

- Slightly sanding the edges first will allow excess sawdust to mix with the glue and disguise the appearance.

- Once the wedge is flush or nearly flush with the surface, smooth the glue into the gap with your finger.

Step 15. Clamp in place and let dry

Clamp the inlay to something that won't stick with glue, such as a block of wood covered with plaster. Leave it in place for 4-6 hours or as long as it takes your glue to dry.

Step 16. Smooth the surface

Remove any excess glue that has hardened and make the inlay flush with the surface of the object using sandpaper, an inlay scraper, or a block scraper.

For oyster or clam shells, polish again with number 300 sandpaper after leveling the surface with coarser sandpaper

Step 17. Cut and place additional plates

Proceed to the next section and follow the same process for cutting the plates and setting them. Remember, the previous slab was intentionally large to create an even overlap effect after you cut it for the slab above it.

Remember to only make the plates bigger at the edges that will be under the other sections. The other edges should fit your design as precisely as possible

Tips

- Alternatively, you can glue all the pieces together first, let them harden, then sand or file off any excess glue. The entire inlay can now be installed as if it were a single piece. This won't look flat like the "overlapping" method already described, but it will save a lot of waiting time for projects with multiple sections.

- Sand the bevelled edge of the inlay to create a beveled edge if it doesn't fit perfectly into the recess.

- You can purchase a wood inlay kit for some routers that will allow you to create recesses, then remove the "shield" around it to cut the inlay to the perfect size. It works best with materials that are between 3 and 6 mm thick, and is easier to use with a movable router than a stationary router.

Warning

- Wear protective eyewear to protect your eyes from small pieces of wood, especially when operating saws and routers.

- Dust from sawing or sanding can harm the lungs, especially when cutting oyster shells or other shells. Use a dust mask and fan to blow dust away from your face.