- Author Jason Gerald gerald@how-what-advice.com.

- Public 2024-01-19 22:11.

- Last modified 2025-01-23 12:04.

Heat management is important in assembling or maintaining a computer. Too much heat can burn sensitive components, especially for overclocked processors. Learn how to properly apply thermal paste as a basic computer cooling science. Follow this guide to find out how.

Step

Part 1 of 3: Preparing the Surface

Step 1. Choose the right thermal paste

Most common thermal paste compounds contain silicon and zinc oxide, while more expensive compounds contain excellent heat conductors such as silver or ceramic. The advantage of thermal paste on silver or ceramic is that it has more efficient heat transmission. However, regular thermal paste will suit most people's needs.

If you're planning to overclock your computer, use a thermal paste made primarily of silver, copper, and gold. It is the most conducive metal to thermal paste

Step 2. Clean the CPU and heat sink surfaces

Wipe the surface with a cotton ball or cotton swab moistened with isopropyl alcohol. The higher the alcohol percentage the better. The level of 70 percent is good but try to use the level of 90 percent.

Step 3. Sand the surface of the heat sink and processor if necessary

Ideally, the two surfaces will be in perfect contact, so no thermal paste is needed. If the base of the heat sink feels rough, you can smooth it out. This is not always necessary unless your primary goal is cooling performance.

Thermal paste is designed to fill in gaps and imperfections in the surface to which it is bonded. Modern production techniques cannot create a surface without imperfections, therefore thermal paste will always be required

Part 2 of 3: Applying Thermal Paste On Cooler With Round Base

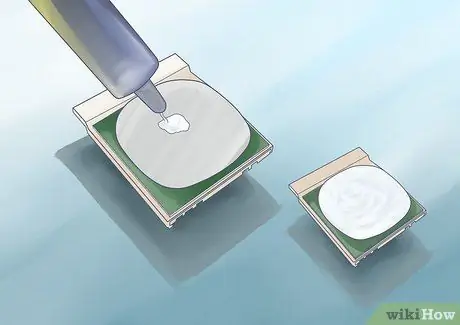

Step 1. Place a small drop of thermal paste into the center of the cooler base

The spread of pasta should be smaller than a grain of rice. If you've ever read that the spread of pasta should be "pea-sized," this is too much, and the pasta could spill over to the motherboard.

You don't need to apply the paste in a circular motion, as the pressure applied will be spread evenly over the entire surface

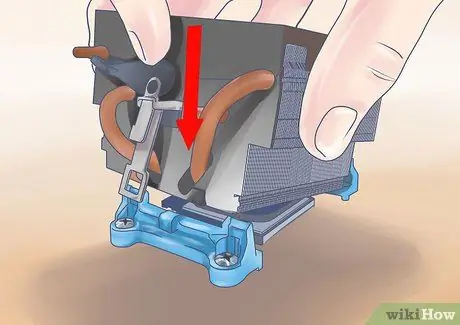

Step 2. Adhere the heat sink to the processor

Install the heat sink with equal pressure from all sides, and the droplets on the surface will be spread over the entire surface. This will create a thin, even layer that will fill in any gaps without overdoing it.

Once applied, the paste will become thinner and spread more towards the edges. This is why it is important that you use a small amount of paste, because a little is enough

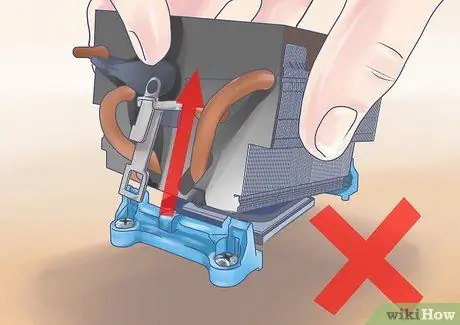

Step 3. Avoid removing the heat sink after installation

It will be difficult to see if the paste has been applied properly. If you break the seal that formed when you attached the heat sink, you will need to repeat this process. Clean the heat sink from the old paste and then reapply it.

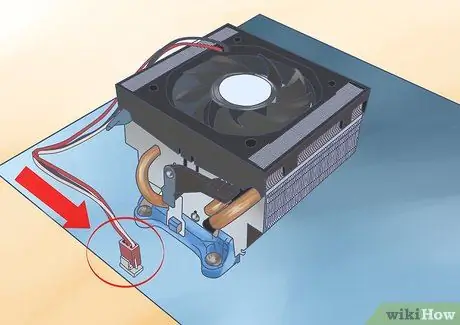

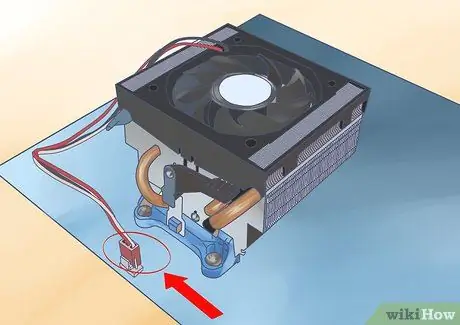

Step 4. Reconnect the fan to the motherboard

The CPU fan wire must be plugged into the CPU fan socket, most of which have a PWM function so that the computer can adjust the fan speed automatically without changing the voltage.

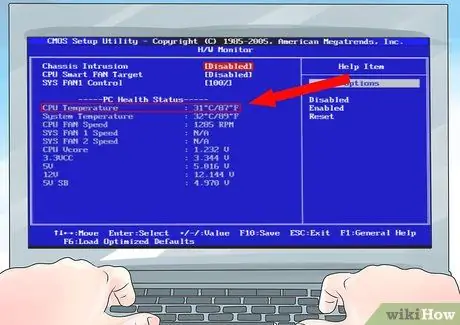

Step 5. Turn on the computer

Check if the fan is rotating. Enter the BIOS by pressing the F1 or Del key while the computer is on. Check if the CPU temperature is normal. The CPU temperature should be below 40 degrees Celsius on standby, just like the GPU.

Part 3 of 3: Applying Thermal Paste On Cooler With Square Base

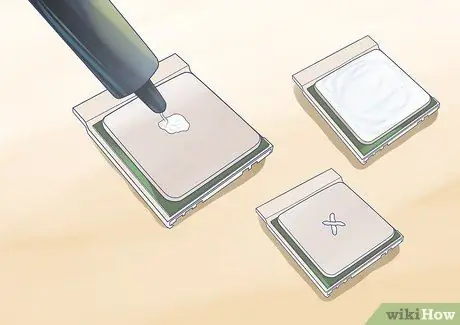

Step 1. Apply the paste to the cooling base

Applying paste to a square cooler is a little more difficult than round, because applying a small drop and then applying pressure can't cover the entire base of the heat sink. There are a number of tricks that can be used in this regard, but we will discuss some of the more popular ones:

- Line method - Place two thin lines of thermal compound on the base of the cooler. the two lines must be parallel and spaced so that each line is one-third the width of the processor. The length of the line should be about one third of the width of the processor.

- Cross method - this method is very similar to the previous method, but the lines are crossed in an "X" pattern instead of parallel. The length and thickness of the line must be the same as the previous method.

- Spread method - This method is one of the most popular and effective, but requires more effort. Place a small amount of thermal paste onto the base of the cooler. Protect your fingers with plastic gloves or a plastic bag. Use your fingers to spread the paste evenly over the entire surface. Be sure to cover all surfaces that will come into contact with the processor, and make sure that you don't use too thin a paste. The paste should barely hide the metal underneath.

Step 2. Glue the heat sink

If you use one of the line methods above, apply even pressure to the installed heat sink to ensure that the paste spreads over the entire surface. If you're using the scatter method, you'll want to place the heat sink at a slight angle to prevent bubbles from forming. Paste that is spread too thinly will produce bubbles after applying pressure.

Step 3. Reconnect the fan to the motherboard

The CPU fan wire must be plugged into the CPU fan socket, most of which have a PWM function so that the computer can adjust the fan speed automatically without changing the voltage.

Step 4. Turn on the computer

Check if the fan is rotating. Enter the BIOS by pressing the F1 or Del key while the computer is on. Check if the CPU temperature is normal. The CPU temperature should be below 40 degrees Celsius on standby, just like the GPU.

Tips

- After cleaning the surface with alcohol, do not touch the surface with bare fingers. Fingers have their own oil which will damage the surface and harm the cooler.

- Keep in mind, thermal pastes often have what's known as a "burn-in-period," when the paste becomes more efficient and continues to lower the temperature. Sometimes this period is very short, but often it takes up to 200 hours.

- If you are using latex gloves to spread the thermal paste, make sure they are flour-free. If flour and thermal paste mix, the heat sink can be seriously damaged.

- Using thin thermal paste is ideal, while thick thermal paste reduces the rate of heat transfer. Thermal paste works to fill in the gaps between the chip and the heat sink, as well as the mini corrugated areas above it.