- Author Jason Gerald gerald@how-what-advice.com.

- Public 2023-12-16 10:50.

- Last modified 2025-01-23 12:04.

Concrete has many uses. Among other things, to build an open porch (patio) and vehicle lane protectors, and also to make statues/sculptures and ornaments. Besides being versatile, concrete is also weather resistant and inexpensive. However, to make use of concrete, you have to be willing to expend the necessary effort.

Step

Step 1. Plan your project carefully

Detailed project planning will save you from various problems in the future.

- Determine the area to be concreted, draw a plan, and record all sizes.

- Determine the final height of the concrete, and record these measurements on the plan drawings.

- Determine the thickness (depth) of concrete, and record these measurements in the plan drawings. A thickness of 10 centimeters is standard for concreting on driveways and garage floors but not trucks or other heavy vehicles.

- Don't forget to make drainage channels and make sure that water won't run to where it isn't expected. The minimum requirement for descent is 1.2 centimeters per meter. However, many people choose a size of 1.8 centimeters per meter.

Step 2. Prepare the necessary materials

You will need Portland Type I cement (for general use) or Portland Type II cement (for structures in water or in soils with a high sulfate content, or if building heat is a particular concern). In addition to cement, you will also need building sand or clean sand, as well as gravel/coral, crushed stone, or lime (crushed limestone).

- Calculate the volume of concrete needed. You do this by multiplying the thickness (in meters) by the area to be concreted (in square meters).

- Provide as much concrete mix as you need for the project. Generally, for an area of 0.093 square meters with a concrete thickness of 10 cm, about 22.7 kilograms of concrete mix is required.

- In general, Portland cement is sold in sacks (paper sacks) weighing 43.5 kilograms. Sacks of cement should be carried with care. If your project is large enough you may need a truck to transport it.

Step 3. Prepare a container for the means of mixing concrete

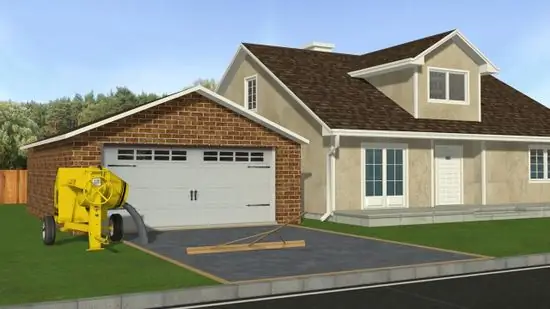

You can buy or make your own from wooden planks. You can also use a wheelbarrow which is usually used to transport materials. If your project is large enough, you can rent a mechanical mixer (molen machine) to reduce manual work.

Step 4. Assemble the concrete mold/formwork

Installation of the mold along the edge of the area to be concreted is very necessary so that the wet concrete mixture remains in place - it does not overflow or wash away.

- Use wooden planks to make concrete molds/formworks.

- Strengthen the formwork boards as best as possible. Make sure the formwork is strong enough to withstand the weight of the concrete mix.

- Check the quality of the formwork.

- If you are piping under the concrete, make sure it is in the correct position.

- Check the dimensions of the formwork, adjust to the sizes listed on your plan drawings.

Step 5. Mixing cement and sand

Prepare a dry mixture by mixing cement and sand. Here are some types of mixtures and their preparation methods.

-

Option 1:

Base mix for mortar (not concrete) made from a mixture of water, cement, and sand with a volume ratio of 1:2:3.

-

Option 2:

Concrete mix for general purposes, made from a mixture of cement, sand, and gravel / crushed stone in a ratio of 1:2:3.

Step 6. Add gravel/coral or rock fragments/breaks

Incorporate the coral/gravel or rock fragments into the prepared dry mixture.

- Add gravel or rock fragments in a ratio of up to 5:1, i.e. 5 parts gravel/rock fragments to 1 part cement and sand mixture.

- Gravel/splintered rock will not affect the tensile strength of the concrete unless you add too much of it. If there are too many gravel/rock fragments, then there will be no more gaps in between where the cement mixture will enter which functions as an adhesive.

- The addition of too much gravel / crushed stone can also make it difficult to get a smooth or even concrete surface.

Step 7. Add water

Adding water to the mixture should be done slowly. While the water is being poured, stir the concrete mixture continuously until it becomes plastic/soft enough to be poured into the mold/formwork.

The plasticity or viscosity of concrete is measured by the "slump value" obtained through the "slump test". The slump test is carried out by filling the fresh concrete mixture into a slump cone made of metal. The mixture of fresh concrete that is still wet is allowed to melt down, then the rate of decrease / concrete flow or "slump value" is calculated. The "slump" of good structural concrete is generally between 7, 5 or 10 cm

Step 8. Completion of mixing the concrete mixture

Continue stirring the mixture until the concrete has an even consistency.

- The texture of the concrete must be evenly distributed throughout the mixture, without the presence of dry parts of the material.

- Continue stirring for two or three minutes to start the hydration process, which is the mixing of cement and water which will affect the hardening of the concrete.

Step 9. Casting and floating of concrete

Pour the concrete mixture into the mold you have prepared. Vibrate the mold by hitting all the edges, the goal is to compact and remove air pockets that may form in the concrete. Let the mixture sit right in the mold, even and constant.

- Use a magnesium rake or a board that has a flat and smooth surface to level the top/surface of the concrete.

- Do this by pulling the tool with the position of the edges slightly tilted up. Drag/drag the rake across all parts of the concrete surface.

- The above process is also known as floating. This process will allow the smooth cement to move to the surface.

- Soft cement dough tends to be easy to shape and easy to smooth by brushing or sweeping it. Leveling can also be done using a trowel/roskam when the concrete begins to harden.

Step 10. Let dry and do the finishing work

After the floating process, let the concrete mixture stand until it becomes stable/strong enough to carry out the finishing process without leaving unwanted scratches.

- Lay out boards or plywood sheets that will allow you to walk on the concrete without sinking into it.

- Crawl on the board or plywood while carrying the tools needed to do the final job, namely smoothing the concrete surface.

- For large enough concrete slabs, you will need a special bull float to smooth the concrete surface and possibly even a trowel. This work is better left to the experts.

- After all the concrete mix has been poured into the mold, cover the area for a few days to protect it from extreme temperatures/heat and rain.

Step 11. Clean the work area from dirt

Collect and wash all concrete mixing equipment/mixers as soon as you are finished using them. Concrete that has matured and hardened is very difficult to remove.

Take enough time to clean all the equipment you rent (a molen machine, for example). Otherwise, you may incur a cleaning fee when you return it

Tips

- There are many types of additives for use in concrete mixes. However, these substances are usually only available in ready-mix concrete packages. Additives are useful for reducing shrinkage of concrete (which causes cracking), increasing work speed, accelerating the setting process, as well as being able to change the color and/or texture of the final result.

- The higher the ratio of cement to sand, the higher the strength of the concrete.

- Make sure the bucket size is ideal enough to make it easier for you to lift and pour the concrete mixture into the work area. A five-gallon capacity bucket (equivalent to 3.785 liters or 4.546 liters) full of dry Portland cement and sand weighs about 20 pounds.

- Use a bucket (rather than a shovel) to get the most precise size when mixing materials. However spades tend to vary widely.

- Prepare yourself to do all the preparation process completely. Start work as early as possible and prepare personal or equipment that will help smooth work.

- If you are mixing more than 0.14 or 0.17 cubic meters for one-time use, you are better off renting a mechanical stirrer (molen machine).

- If you are not confident in your ability to mix raw materials, you should use a ready mix (premixed) concrete. The mixture is usually pre-measured as needed and packaged for ease of use. On the container generally written detailed instructions for mixing and processing.

- To make stronger concrete, insert 0.95-2.5 centimeters of reinforcing bars into the mixture that is still wet or can be installed before the mixture is poured. This method can help with various voltage loads. Mixing in fibers (glass or plastic) can also help.

Warning

- Wear boots and rubber gloves to protect your feet and hands when in direct contact with the wet concrete mix.

- Portland cement can cause burns to unprotected skin.

- Do not breathe dust from Portland cement or let it get into your eyes. Wear a nose cover (respirator) and safety glasses.