- Author Jason Gerald gerald@how-what-advice.com.

- Public 2023-12-16 10:50.

- Last modified 2025-06-01 06:05.

Epoxy is a permanent adhesive used on a variety of surfaces, from plastic to metal. Once it has hardened, the epoxy can be difficult to remove. Epoxy is originally a liquid. When mixed, it will heat up and will eventually cool and harden. You can remove the epoxy by returning it to its original state (i.e. liquid), or at least a gel so that you can scrape it off the surface of the object. Removing the epoxy is actually quite easy, as long as you take the proper precautions and be patient.

Step

Method 1 of 3: Heat Remove Epoxy

Step 1. Wear gloves, safety glasses, and a respirator that has gas and vapor cartridges

When the epoxy is heated, it releases steam that can irritate the lungs, eyes, and mucous membranes. To protect yourself, wear safety glasses and a respirator that can filter out vapors and gases. Also wear rubber gloves with a length of at least 8 cm that extends beyond the wrist to protect the skin. We recommend that you also tie the hole with a rubber band to provide additional security.

- The best type of respirator cartridge depends on the epoxy material. Check the Material Safety Data Sheet (MSDS) on your product to find out what type of respirator cartridge and other equipment is required.

- Make sure the safety glasses fully cover your eyes and adhere to your skin, without any openings for air to enter. Alternatively, you can use an PPE respirator mask (personal protective equipment) that has built-in eye protection.

- Always test the mask to see if it can be used properly and tightly. If the mask doesn't fit well, you may need to trim your facial hair or use a more suitable mask.

- If you smell a strong chemical odor when you put on a respirator, it may be that the respirator is not working properly or the cartridge needs to be replaced. Get out of the room immediately so you can check the respirator and make any necessary changes.

Tip:

The respirator cartridge is color coded to match the type of filtration provided. For example, if the epoxy you're working with contains organic vapors, use cartridges coded yellow, black, or olive.

Step 2. Wear clothes so that they completely cover the skin

Wear tight pants and long-sleeved shirts. If you're wearing a button-down shirt, make sure you've closed all the buttons. This is to prevent the skin from reacting with the steam that may arise when you heat the epoxy.

Step 3. Soak the surface of the object in acetone for at least 1 hour

If the epoxy sticks to the wood surface, soak the area in acetone for 1 hour before softening it with heat. You can soak the object in acetone, or you can drip acetone over a surface that has epoxy on it. Acetone can only seep on the surface of the wood.

When handling epoxies that stick to plastic, cement, marble, vinyl, and metal, any chemical will interact with the surface, but not seep into the object, as is the case with wood

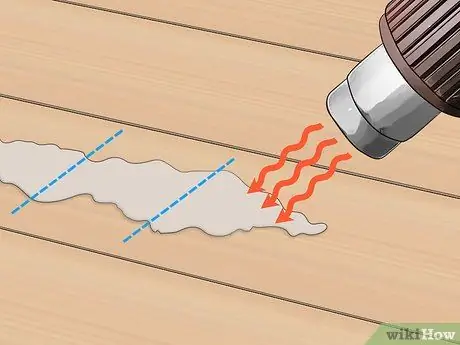

Step 4. Point the heat gun (a heating device similar to a hairdryer) at the epoxy for a few minutes

This is to increase the temperature of the epoxy to over 90 °C (this is the softening point of the epoxy). Move the heat gun in small strokes, not holding it in one place for several minutes at a time. When handling epoxy on wood or plastic surfaces, pay close attention to the surface so you don't overheat and burn.

- You can use a soldering iron to replace the heat gun. After the soldering iron is hot, directly attach the tip to the area where the epoxy is attached. This makes the epoxy soft.

- If the epoxy is on an object instead of a floor tile, place the object on a hot plate. This will have the same effect as using a heat gun, and the tools are easier to obtain.

Step 5. Heat a small area at a time

Do not heat all parts of the epoxy if you cannot keep the entire epoxy hot for a long time. Instead, heat up section by section about 5-8 cm long. After one section is complete, continue with the next section. This way, you can scrape off the exposed edges more easily.

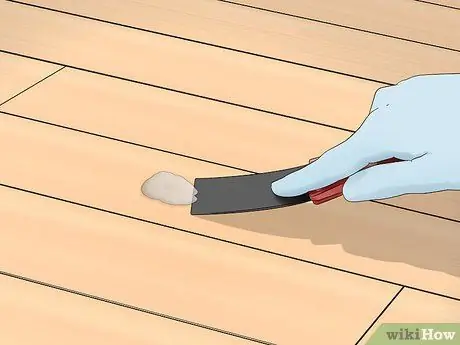

Step 6. Use a plastic scraper to scrape off the hot epoxy

Remove any epoxy that has stuck to the surface using a strong plastic scraper. There may be parts of the epoxy that have not heated up. If this happens, reheat the area and scrape everything off until all the epoxy has peeled off.

- Do not reheat a newly heated area. Wait a few minutes for the epoxy to cool before you reheat it. Otherwise, the area may catch fire.

- Do not use a metal scraper as this may damage the surface you are working with.

Method 2 of 3: Freezing the Epoxy

Step 1. Wear gloves, safety glasses, and a breathing mask equipped with vapor and gas cartridges

Like epoxies, refrigerants (coolants) contain harmful vapors that can irritate the eyes, skin, lungs, and mucous membranes. Wear tight-fitting safety glasses so no air can enter, and a tight-fitting respirator mask with gas and vapor cartridges. Also wear rubber gloves with a length of at least 8 cm that extends beyond the wrist to protect the skin.

- Refer to the MSDS (Material Safety Data Sheet) for the epoxy and refrigerant you are using. This data sheet will provide instructions on how to safely handle both materials, and what protective equipment is required, including respirator cartridges.

- Check respirator manuals, such as the 3M Cartridge and Filter Guide, to determine the correct color code for the required respirator.

- Find out if the refrigerant you are going to use is legal in your area. Certain types of refrigerants should not be used because they are harmful to the environment.

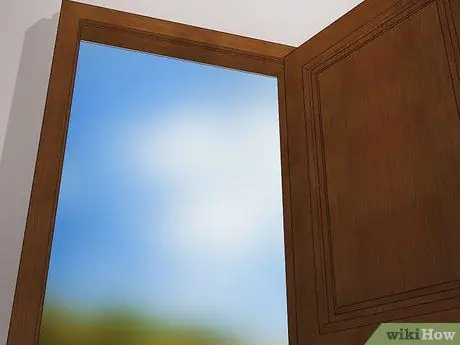

Step 2. Open doors and windows

This is so that the air can flow freely and carry the refrigerant vapor out of the room. If the windows and doors are not opened, the smoke will build up and can be dangerous if inhaled. When a stream of air containing chemicals moves, you should take pets and children to a safe room and keep the door closed. This is to prevent them from sucking in the smoke.

Make sure you have turned off the air conditioner or heating equipment to prevent the steam from being inhaled

Step 3. Shake the refrigerant can

You can buy refrigerant in spray cans at hardware stores. If you are using canned refrigerant, shake the can before use, just as you would any other spray can. Next, hold the can about 30 cm from the epoxy to be handled. Make sure you position the can upright so the liquid doesn't seep out.

Step 4. Spray refrigerant on the epoxy

The refrigerant will quickly lower the temperature of the object it touches. The epoxy will freeze immediately and become brittle. DO NOT place hands around the sprayed area. Make sure you wear gloves and safety goggles properly before spraying. Do not allow pets and children to approach the area.

Step 5. Pry the epoxy that has turned brittle

Use a plastic kape (putty knife) to pry off the epoxy or pound the epoxy with a rubber mallet. Because it has frozen, the epoxy will be easily crushed into crystal grains. Next, sweep and put the epoxy granules into the dustpan (cikrak), then throw it in the trash. You can also vacuum it with a vacuum cleaner to remove all epoxy crystal flakes, including very small ones.

Be careful not to damage the surface of the object when you apply strong pressure to crush the epoxy. If the epoxy doesn't break down easily, try spraying more refrigerant to make the epoxy cooler

Method 3 of 3: Chemically Removing Epoxy

Step 1. Wear safety glasses, gloves, and a respirator mask with vapor and gas cartridges

Before handling any chemicals used to dissolve and soften epoxy, you should wear safety equipment to protect your eyes, mucous membranes, lungs, and skin. Wear safety glasses that fully cover the eyes and adhere to the skin without openings to allow air to enter. You will also need a respirator with cartridges suitable for the chemical you are handling, and rubber gloves that are at least 8 cm long that extend beyond the wrist.

Read the MSDS for the chemical solvent and epoxy you're working with to find out what type of respirator cartridge you need

Step 2. Open doors and windows

This is very important because you need ventilation and airflow. Circulation of air through open windows and doors will allow hazardous chemical fumes to flow outside the house. If the doors and windows are closed, you are more likely to inhale chemicals that are hazardous to health.

Make sure you turn off the air conditioner or heating device to prevent fresh air from drawing chemical fumes into the room

Step 3. Use a chemical that can soften the epoxy

You should also choose a chemical that won't damage the surface to which the epoxy is attached. Chemicals can damage the surface of certain objects, such as plastic, fabric, and vinyl. Even strong chemicals can scrape the surface of an object before the epoxy glue has softened. Always check the MSDS for the chemicals used! The MSDS will include handling instructions and a list of PPE (Personal Protective Equipment) that must be used.

- Avoid using class 3 and 4 oxidizing agents. These materials can cause an immediate fire, or catch fire when used.

- Try using paint thinner. The acetone found in most thinners can soften tough epoxy, but you'll need to soak it in the thinner for at least 1 hour.

- Use a commercial exfoliating product. You can buy it at a hardware store.

Step 4. Use an exfoliating product

You can either drip it directly on the epoxy or pour it onto a washcloth and rub it over the epoxy. Whichever product you choose, make sure that the peeling agent absorbs into the epoxy in sufficient quantity. Once the product has been applied, wait at least 1 hour before you remove the epoxy.

- Do it little by little, about 5-8 cm at a time. If the area is too large, the chemicals may not be able to work effectively.

- Make sure pets and children stay away from the room when you apply this chemical.

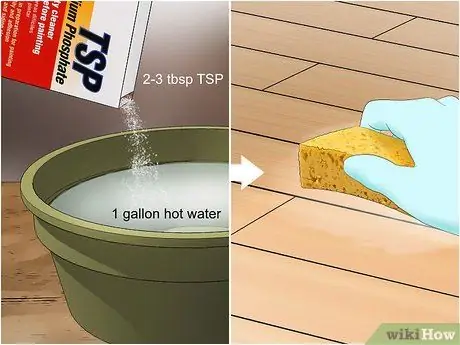

Step 5. Make a cleaning solution

After the exfoliating chemical has been left for 1 hour, you must neutralize it before scraping off the epoxy. Use a medium sized bucket to mix 2-3 tbsp. (50-80 grams) trisodium phosphate and 4 liters of hot water. You can pour this mixture directly onto the exfoliating chemical, or you can apply it with a sponge. Let the cleaning solution sit there and neutralize the chemical for at least 5 minutes.

Step 6. Scrape off the epoxy stuck to the surface

Scrape the epoxy using a sharp, strong plastic scraper. Place the scraped epoxy shard on a paper towel, then throw it in the trash. It aims to get rid of the chemical as far as possible. If there is still some epoxy on the surface, soak the epoxy in the chemical for a long time before you scrape it off again.

When all the epoxy has peeled off, clean the surface area with a cloth dampened in warm soapy water. Don't let chemicals stick to objects around you, especially if you have pets and children in the house

Tips

- We recommend that you seek advice from a hardware professional. Sometimes, epoxy can also be removed with household products. Professionals can usually suggest the best product for removing epoxy.

- Try removing the epoxy 2 to 3 times. Sometimes the method you apply can only remove the top layer of the epoxy. Repeat the process until the entire epoxy layer is gone.

Warning

- Take children and pets to a safe location when you apply chemicals to the epoxy.

- Allow air to move freely throughout the house, and make sure the air conditioner or heating is turned off. Do not allow harmful chemical fumes to get trapped inside the house.

- Make sure you are wearing gloves, safety glasses, and a mask properly. Do not let any smoke that can get into the mouth, skin, and eyes.