- Author Jason Gerald [email protected].

- Public 2023-12-16 10:50.

- Last modified 2025-01-23 12:04.

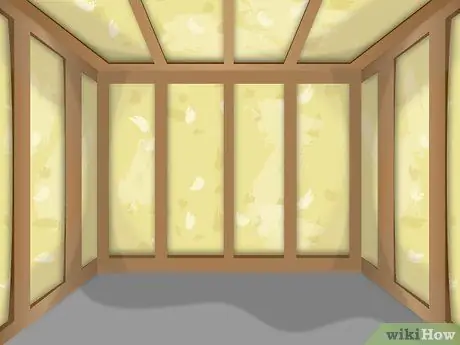

Insulating (installing an insulator) in the warehouse space will reduce damage to your equipment, supplies or storage boxes. It also makes the room more useful, so you can put plants in it or use it as a recreation room. You need to close any gaps in order to properly insulate a shed. Install the insulation sheet and if possible cover everything with gypsum board.

Step

Part 1 of 3: Closing the Cracks

Step 1. Replace the broken window

There's no point in insulating walls if your windows are gaping or broken.

Step 2. Consider installing two-layer windows

This is important if you intend to use it in your living room or workspace, as single-glazed windows will dissipate most of the heat and depending on which side your shed is facing, will let hot air in during the summer.

Step 3. Seal gaps in the roof, outer covering and around the foundation

Cover small cracks with putty. Use a special type of foam spray that expands for larger holes.

Step 4. Observe the shed when it rains, to see if there is any seepage of water

Install a roof with a good drainage system. You can use shingles, roof metap or fiberglass.

If there is no rain, use a plant sprayer and spray it towards the roof. Look inside for signs of seepage

Step 5. Consider using the sideways technique on the outer siding if there are a lot of gaps in the shed boards

Closing the hole and making a cover on the outside is important if you want the indoor temperature to remain constant. Look for dark stains on the walls to see if there is water seepage in the shed.

Step 6. Purchase a waterproof door

Most warehouse room materials are not made to waterproof specifications. Maybe you need to buy a special size if your barn door is smaller than the standard door size.

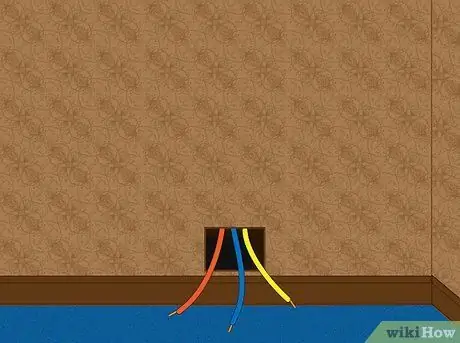

Step 7. Plug in the proper electrical wiring, if you want to install space heaters or lights

Ask an electrician to make sure these cables are secure. Wire connections from homes are usually not safe enough to use.

Part 2 of 3: Choosing an Insulator

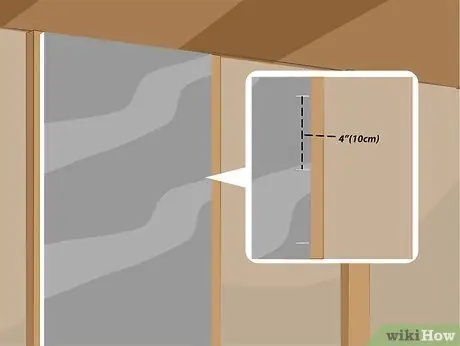

Step 1. Measure the distance between the pile boards

This distance indicates the width of each sheet or pad of filler that you are going to purchase.

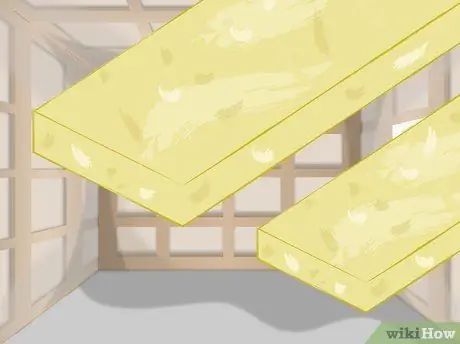

Step 2. Choose an insulating layer or filler if your planks are 45-60 cm apart

This standard wall size will make it easier for you to spread and secure the insulation between the planks, rafters and beams. This method is relatively expensive and is best applied to unfinished walls.

Step 3. Replace with foam board or polystyrene sheet if the post boards are of non-standard length but spaced regularly

The board or foam is quite thin but and good enough for this purpose, although of course not recommended if you install a lot of sockets.

Step 4. Choose a wool insulator if you need insulation that can withstand high temperatures

Although the insulator made of fiberglass has a similar function, fiberglass must be given another coating to be safe for humans.

Step 5. Choose foam, loose fill or insulating spray if the warehouse walls are already covered with gypsum

You can make holes and spray the material into the frame.

Step 6. Choose an insulator in the form of a reflective sheet if you want to do it yourself on a standard frame

This material is flexible so it can bend at corners or in other difficult positions.

Part 3 of 3: Installing the Insulator

Step 1. Hire a professional contractor if you choose a spray or foam insulation model

Some types of methods require special equipment.

Step 2. Take your warehouse size with you when you go to the building shop

They can help you with your shopping so that you can get what your warehouse needs. They will ask you to measure the spacing of your planks.

Step 3. Lay out the filler bearing sheet or horizontally

Place the polystyrene on the frame.

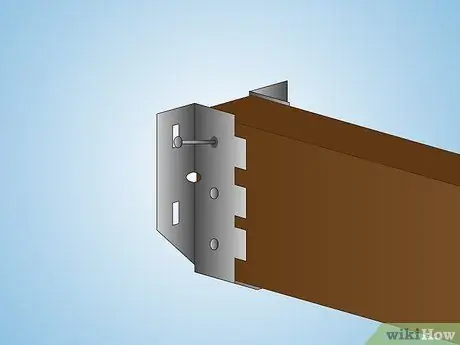

Step 4. Adhere the filling pad with firing adhesive if you are using foil or filler sheets

Nail into the planks. You will need to attach the polystyrene sheet to the walls and post boards with special glue.

Step 5. Make sure that the ends of the insulating sheets overlap each other at their junctions

Continue until the walls are covered, horizontally. You can cut this insulation sheet with scissors to make smaller sections.

Step 6. Insulate the ceiling as well as the walls

Leave a gap of about 5 cm between the top of the ceiling and the insulation to prevent moisture.

Step 7. If you want an attractive warehouse interior, cover the insulating sheet with a layer of gypsum

First, hang the sheet from the ceiling, then proceed to the wall.